How about saving millions?

Nov 22, 2013

Until now, paper and board makers in China have been focusing all their attention on increasing their output in tonnes. Based on this approach, a paper machine is not considered to be functioning well if its output in tonnes drops, even if this is due to improved bulk and reduced use of fibers. The box makers are not willing to pay premium rates for lighter products, neither – even though they are able to produce more boxes with the same amount of tonnes. According to Xiandong Ji, General Manager of Zhuhai S.E.Z. Hongta Reheng Paper Co., Ltd., this era is gradually coming to an end. Environmental considerations and fiercer cost competition are forcing box makers to rethink their processes. Whichever way you look at it, boxes are not made of tonnes but board sheets.

|

“The day will soon be here when paper and board users realize that they need to buy in square meters instead of tonnes,” says Xiandong Ji, General Manager of Zhuhai S.E.Z. Hongta Reheng Paper Co., Ltd. |

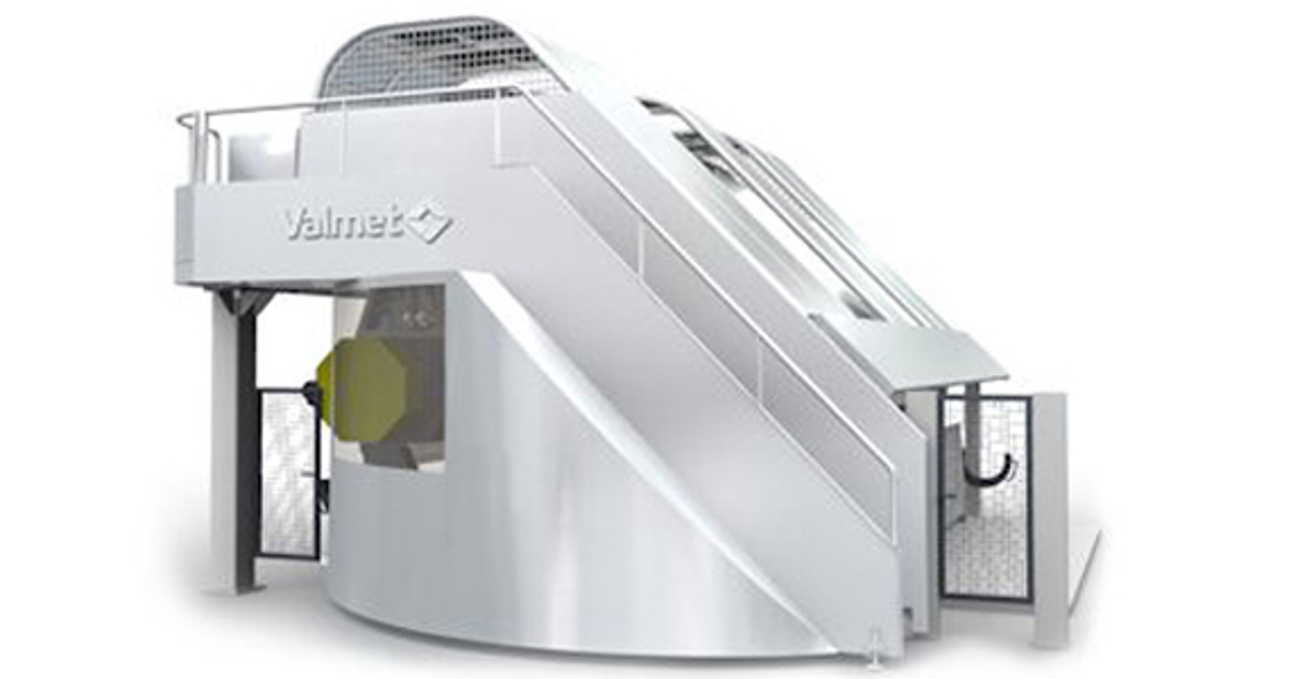

Extremely high-quality board with high bulk is a reality with Zhuhai S.E.Z. Hongta Reheng Paper’s PM 2 board making line and Valmet’s (until Dec. 31, 2013 Metso Paper) ValZone metal belt calender. The Hongta PM 2 achieves high surface smoothness, and they are aiming for lower and lower basis weights. “The low-weight trend is really growing in China. Today, we are producing boards with basis weights of 210 g/m2 but we plan to further lighten the basis weight to as low as 200 g/m2,” confirms Xiandong Ji. According to him, the reasons for reducing board weight are “building image, getting environmentally sounder products and a lower price, and using less fiber”. For paper makers, “it’s just about saving cost”.

Boxes made of board sheets, not tonnes

When one is producing e.g. cigarette boxes, the actual board tonnes do not matter. What matters is the surface area per tonne. “Most of the box makers still buy in tonnes rather than square meters. We have a fixed arrangement with some box makers, which eases the situation a little. But buying in tonnes will also see a gradual change. The day will soon be here when paper and board users realize that they need to buy in square meters instead of tonnes,” says Xiandong Ji.

How about saving millions?

When focusing on lowering basis weights of paper or board, it is important to be open-minded. If you just focus on making and buying in tonnes with predefined basis weight, you will never be able to achieve the benefits of lowering weight. What if cigarette board of 200 g/m2 would easily equal a heavier grade of 210 or 220 g/m2? In these cases, the raw material savings alone are substantial and amount to millions of euros. To be among the first to change one’s viewpoint will require a certain amount of courage, but such a change will result in a greener image with substantially lower cost. It is certainly worth paying a little more per tonne of board. The ValZone metal belt calender is only one of Valmet’s numerous solutions for improving bulk and lowering basis weight without a deterioration in the strength or surface quality.

Sounds hard to believe? Let’s calculate this together using your numbers. It all ends up in cost savings.

More money for the board producer

How to sell lighter product with price premium

Cost savings are enormous when bulk is increased, i.e. basis weight decreased. The calculations consider only direct savings.