Uhle boxes - care, handling, cleaning, maintenance and adjustment

Jul 30, 2019

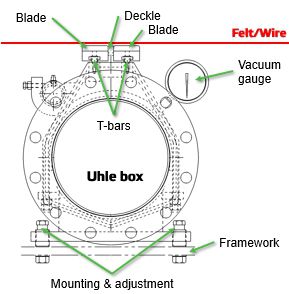

The uhle box is custom designed to fit new and existing paper machines and several arrangements to fit any application. Typically the boxes are equipped with two or three blades or a specially designed cover (such as the perforated Valmet Uhle Box Cover).

Handling

Boxes with installed ceramic should never be lifted via the ceramic covers or foils, or any water or vacuum piping. Only lift at the box body or designated lifting points.

When transporting the uhle box via forklift, if the uhle box is packed in a wooden crate, it must be lifted only at the indicated points. If the uhle box is not inside a crate, proper protective shoes for the forklift forks must be used in order not to contaminate the stainless steel uhle box surface.

Cleaning blades (foils and covers)

Cleaning of the ceramic elements of the uhle box can be done with high-pressure equipment. Cleaning should be done as soon as possible after the wire/felt is removed.

The maximum pressure is 100 bar (1450 psi), maximum water velocity 30 l/min (8 gpm) and maximum temperature is 60 ºC (140 ºF). Cleaning with higher pressure or temperature or larger volume of water or with jet nozzles can cause damage to the fiber reinforced plastic material and the ceramic.

|

CAUTION: Use extreme caution while handling the washing hose in order to avoid any mechanical damage to the ceramic. |

|

CAUTION: After cleaning with steam, the ceramic should never be rinsed immediately afterward with cold water, in order to prevent thermal shock. |

Normal maintenance

While the machine is operating, check the following items regularly:

- Visually check the ceramic, looking specifically at the surface and edges for breaks, cracks, loose segments and the bond line.

- Verify that the box is still firmly bolted to the frame.

- Make sure all dewatering elements, piping and screw connections are correctly connected to the box.

- Verify that the box is operating without undue vibration.

- Check to make sure all vacuum levels are at the desired levels.

- Verify that drainage is even and trouble free over the entire machine width.

|

CAUTION: If any damage is found (especially on the ceramic surface) immediately start a failure analysis and contact the ceramic manufacturer. Otherwise serious damage may occur! |

Changing foils

If any foils are swapped out during a shutdown, the existing foils should be removed as soon as possible after the machine stops. This will prevent the foils sticking in place due to drying deposits.

Adjustment

Height of the uhle box, i.e. penetration into the wire/felt by the uhle box blades, can typically be adjusted with mounting bolts on the sides or underneath the uhle box where it mounts to the framework.

The distance between blades can typically be adjusted also. In an example Valmet delivery with one uhle box equipped with ceramic blades, and the other uhle box using poly blades, the distance between the blades could be adjusted in steps: 0.50”, 0.625” or 0.75” based on the T-bar used. Always refer to the uhle box delivery drawings for the correct adjustment and layout for your uhle box.

For more information on uhle box operation and maintenance, contact your Valmet representative.