Common fluids valves explained: Cartridge pressure relief valve

Nov 27, 2018

Pressure relief valves are used to prevent over pressurization in the hydraulic circuit. They are located close to the pumps and reservoir tank or close to the equipment to safeguard from over pressurization.

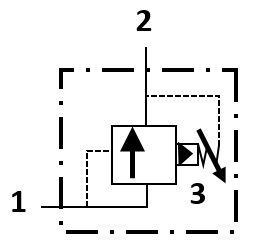

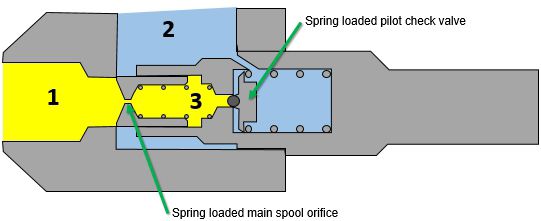

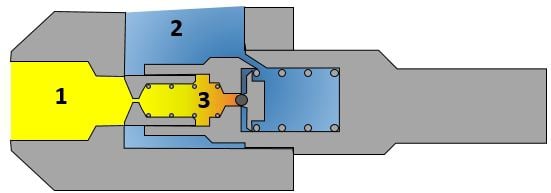

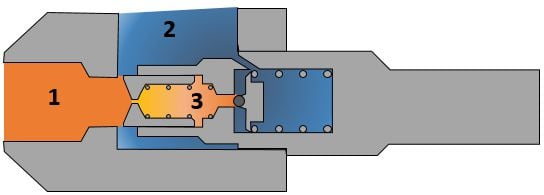

Turning the pilot spring screw clockwise increases the force exerted on the pilot check ball. This will increase the pressure at which the valve opens up. As pressure in port 1 increases, oil flows up the main spool orifice and lifts the pilot check ball. When the check ball opens, a small amount of oil is exhausted to port 2. This creates a pressure drop across the main spool orifice. This pressure drop lifts the main spool and opens the main path from port 1 to port 2. Pressure in port 1 will remain at the valve pressure setting. Dumping continues as long as there is flow past the pilot check ball.

Stage 1: Pressure is below valve setting

In stage 1, the pressure is below the valve setting. There is small leakage around the main spool to port 2.

Stage 2: Pressure in line 1 increases

In stage 2, as pressure in line 1 increases above the valve setting, the pilot check valve opens and some oil flows to port 2. This flow creates a pressure drop across main spool orifice.

Stage 3: Pressure drop opens main spool

In stage 3, the pressure drop across the main spool orifice opens the main spool, dumping main port 1 to main port 2. When port 1 pressure decreases, the pilot ball check valve will reseat itself, eliminating flow through the pilot check. With no flow, the main spool spring will reseat the main spool and stop flow to port 2.

Pressure relief valves are adjusted to stay closed under normal operating conditions. They are not an efficient way to set system pressures as heat and noise are generated when the valve is open (recall that temperature rises when no useful work is being done). If a relief valve and downstream oil lines are hot, the valve is open and dumping oil. The relief valves are the first things to check if your oil is running hot. Verify system pressures are on target as well as the setting of the valve.

For more information on maintaining your hydraulic system, contact your Valmet representative.