Blade doctors - purpose, design, operation, examples and options

Jan 28, 2020

NOTE: Although doctors are used with rolls or dryer cans, the term "rolls" will be used to refer to both in the following discussion.

Purpose of the doctor

Foreign material can accumulate on rolls, affecting the quality of the web and damaging soft rolls. Doctors are used to scrape this material off the rolls. Doctors are also used to redirect the web to prevent wrapping around rolls (especially during threading or after a web break). Web wrapping can damage equipment and increase the risk of injury to personnel from flying objects.

Doctor components, loading and unloading

Doctor operation

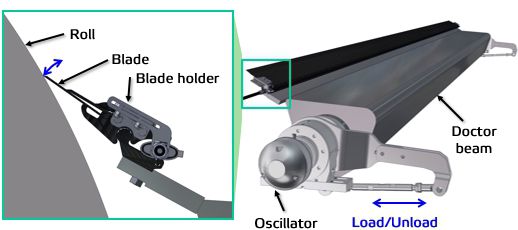

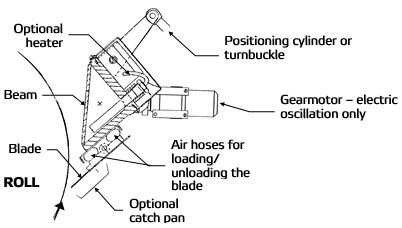

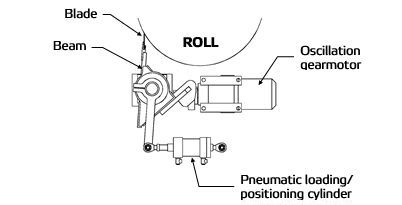

Blade type doctor assemblies typically consist of a support beam and blade which span the length of the roll face. Whenever the roll nip is closed and rotating, the blade should be loaded against the roll. Where applicable, the entire doctor assembly should be oscillating in a cross machine direction. This oscillation promotes a more uniform wear on the roll and blade.

Doctor design

The doctor blade is typically loaded against the roll using one of the following methods:

- An air hose, located in the blade holder assembly, is inflated while another one is deflated. The combination of inflating one hose and deflating the other pivots the blade toward or away from the roll. The beam does not move.

- Loading cylinders (typically pneumatic) pivot the entire beam/blade assembly to load the blade against the roll.

During oscillation, the entire doctor assembly is typically moved back and forth about ±.375" in a cross machine direction. Oscillation is common, but not present on all doctors. Oscillation is typically accomplished using one of the following methods:

- an electric gear motor

- alternately inflating/deflating air bags located at each end of the doctor beam

All roll doctors have at least two positions: loaded and unloaded. In designs where the position of the beam does not move during loading (ie: air hose loading), there is usually a way to re-position the beam. A pair of turnbuckles are used when manual adjustment of the beam is sufficient (typically used for installation). A pair of cylinders are used when re-positioning is done more frequently (such as during threading or blade changes). This may be due to operating needs, space limitations, or maintenance.

Examples of typical doctor assemblies

(a) Doctor assembly with air hose loading (shown with electric oscillation, catch pan, and electric heater)

(b) Doctor assembly with cylinder loading and motor oscillation

Doctor options

There are several options which can be combined with most roll doctor designs. For instance:

- In machines where the scrapings would tend to fall onto the web, a catch pan (also called a saveall pan) can be added. Catch pans need to be cleaned out periodically. Make sure to lock-out the machine before cleaning catch pans.

- Heaters are sometimes added to doctor assemblies in systems with steam showers. Heaters can be electric or steam and are designed to uniformly heat the length of the beam. The heaters are added to prevent condensation from the steam showers which could drip on the web.

- Doctors may have multiple blades.

- Air blows may be mounted on the doctor (typically along the face of the beam) to assist in re-directing the web.

Refer to the project drawings and bills of material for specific design details for the doctor which was supplied for your machine. For typical doctor maintenance instructions, read the Up & Running article found in the "Field Report - Roll doctor maintenance" article in the Related Links section.

For assistance with improving your doctoring process, contact your Valmet representative.