Avoid the wrinkles and web breaks that result from poor splicing

Aug 4, 2020

Arguably, no procedure in papermaking is as underestimated as splicing. Often approached with a "better done and forgotten" attitude, splicing offers no rewards for a job well done and stiff penalties to a mill's bottom line for poor quality workmanship.

Poor splices lead to wrinkles and breaks in downstream processing

Splices have changed little in 200+ years of papermaking. Standard techniques provide a degree of uniformity, however, each handmade splice is unique. The quality of the splice depends entirely on operator proficiency. The slice must be capable of withstanding the tension of a customer’s process, which in some cases can impose up to five times the tension of a winder.

A failed splice in just one roll can result in a customer returning an entire shipment. These defective rolls must be rewound at the mill, where winder operators inspect each splice, and re-splice weak areas. More than one hour must be devoted to each roll to correct the problem. A two-ton roll of paper can cost a mill thousands of dollars to produce, portions of which must be reinvested to repair failed splices.

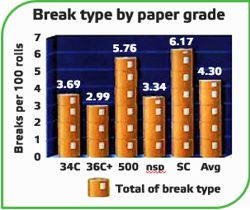

A single bad splice is not an isolated incident. Up to 20% of all splices fail, with most occurring in the winding operation. However, splice breaks at the coater, supercalender or other machine areas require everyone to perform splices at some point.

A necessary evil

While lacking consistency and quality control, splicing remains necessary to produce a continuous web. Given the fact that a splice adds a foreign object to the plane of the paper, it's easy to understand the problems it produces. Not unlike a knotted rope attempting to pass through a nip, a splice must either lift the nip roller or compress in order to advance. The increased tension level produced, combined with existing defects in the web, results in a sheet break.

Improper tension, which lies at the heart of all splice-related problems, often produces wrinkles. Delaminated and weakened fibers produced by a wrinkle serve to weaken the web. When subjected to higher tensions, the weakened web often breaks at or near the splice.

Splice-related wrinkles

Splice problems such as hard, crepe, and blow wrinkles commonly lead to sheet breaks. Hard wrinkles are formed at the winder immediately after a snap-off. As the winder comes to a stop after many nip cycles, layers of paper drape loosely on the roll. After splicing and winder start-up, several revolutions are necessary to tighten the loose paper through nip mechanics. During tightening, a bubble forms immediately before the back winder drum nip and randomly proceeds through the nip. A parabolic wrinkle is formed, often near a splice. The apex of the wrinkle is usually at the splice, with the break occurring a short distance away.

Blow wrinkles are usually associated with a tear along the splice edge. The tear creates a void in this area. This void or tear along the splice can occur in the roll during layer-to-layer slippage in the nip after start-up. The wrinkle itself is created by the customer running the sheet through their process.

Crepe wrinkles typically form as a result of paper slippage in poorly built-up rolls, and excessive caliper variation of the sheet. These wrinkles are primarily found in the areas below a splice after a web break. Paper severely weakened in creped areas often fails in successive processes.

Failing to make the grade

Winder operators must understand that a paper splice does more than merely hold two sheets together. When made successfully, a splice maintains a continuous paper converting process designed to yield high productivity and operating efficiency.

But more so, the paper splice represents the strength of the bond between the papermaker and the customer. It ensures a product that can be trusted to deliver quality, usable paper. Additionally, it helps protect the credibility a mill's future is built on.

Splicing recommendations can be found in a couple of articles in the Related Links section. For more information about the cost of poor splicing, or technology such as the automatic butt-joint splicer, contact your Valmet representative.