Substantial savings through efficient waste heat utilization at SCA Packaging Obbola

May 10, 2011

Peter Brunesson, Project Manager at Obbola (right) and Jori Byskata, Project Manager at Valmet, are shown in front of the BVN silencer on top of the heat recovery stack. They are both very pleased with the results of the rebuild.

In a modern paper or board machine, the effect of heat reclaimed from dryer section exhaust air can translate to over 40 MW of energy saved during periods of peak heating. But the benefits of effective heat recovery are by no means restricted only to such cases, since, in practice, notable savings can be reached at all times in all types of machine. A recent heat recovery system rebuild at SCA Packaging’s Obbola PM 1 kraftliner machine in Sweden yielded energy savings of over 11 MW.

The dryer section is the biggest consumer of thermal energy in the paper machine. As almost all excess energy leaves the dryer section with the hood exhaust air, this is an excellent source of heat. Heat recovery provides substantial energy savings, with the payback times of heat recovery investments being usually less than one year.

It is vital when rebuilding a heat recovery system to pay attention to the noise impact of the new system. Due to regulations prohibiting mills from increasing current noise levels, noise abatement measures must be undertaken.

11 MW of heat returned to process

The Obbola PM 1 is a kraftliner machine producing 435,000 t/y. Process water was heated by excess heat from the old evaporation plant. However, when the plant was rebuilt, there was no more surplus heat available. Thus, a new way of heating process water in an economical way had to be found.

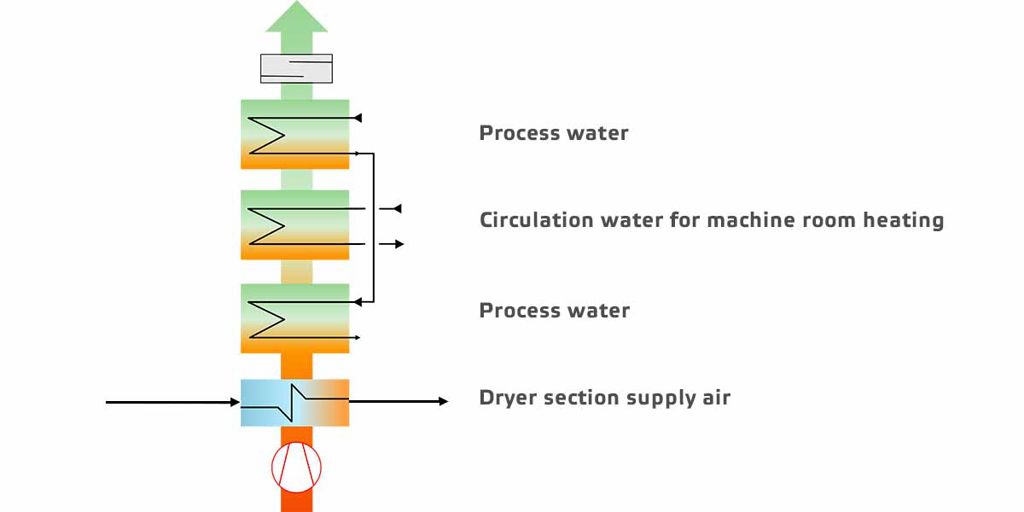

In this case, the solution was to completely rebuild the existing heat recovery stack No. 3. The target was to maximize heat recovery from the new stack. The need to optimize heat recovery, emphasizing maximum heat output to the process water, while still being able to sufficiently heat the circulation water for machine room heating, resulted in the solution shown in Figure 1.

Figure 1. The heat recovery solution at Obbola.

The achievable heat output was:

- 870 kW to the dryer section supply air

- 6,900 kW to the process water

- 3,700 kW to the circulation water for machine room heating

The result of the rebuild fulfilled all expectations. The total heat recovery effect from a single stack adds up to over 11 MW. At present energy prices, the payback time for this complete investment exceeded SCA's expectations.

The environmental concerns of SCA Packaging’s Obbola paper mill also extended to noise control. As the mill is situated close to the village, noise abatement requirements resulted in a guarantee sound pressure level of LpA = 70 dB, measured according to ISO 3746.

Installation of the new heat recovery stack meant that noise generation also had to be taken into account.

Based on this requirement the heat recovery stack was equipped with Valmet Sound Attenuator BVN*, dimensioned to the guarantee sound level at the discharge. Like the other modules of the Compact Heat Recovery stack, the attenuator is also a modular part of the package.

Heat recovery offers substantial savings potential

There is big savings potential in air systems and drying processes. Usually there is a need to heat hood supply air, process water, white water and circulation water for machine room heating.

The available waste heat sources are mainly hood exhaust air and other exhaust air from the dryer section, and turbo blower exhaust air. The very high-temperature exhaust air from the air dryers and impingement drying offer an extremely good heat source. Flash steam and condensate from the drying process are also well suited to heat recovery.

Up to 50-60% of the energy in hood exhaust air can be economically recovered. Water can be heated up to 50-60 °C without additional steam heating. The hood supply air can be heated to approximately 55-60 °C, and, with flash steam and/or condensate, close to 100 °C. In colder climates, the machine room ventilation air can be heated almost completely with recovered heat.

The rationale for using heat recovery is that it replaces external energy (which would generate costs) with reclaimed heat in an economically profitable way. As a starting point, the mill’s heat requirements should be surveyed and the flows to be heated with reclaimed energy should be determined. Similarly, the available heat sources should be identified.

Energy analyses and air systems audits include evaluations of energy consumption and heat recovery efficiency, and more detailed estimations of the energy saving potential of the air systems. At today’s energy prices, achieving viable pay-back times for additional heat recovery investments is fairly easy.

By using modular solutions, supplementary heat recovery can easily be installed as additions to existing stacks or as stand-alone systems. There is a wide range of heat exchangers engineered to heat air and fresh or fiber-containing water.

Valmet’s Compact Heat Recovery is a space-saving solution for a wide range of applications. Its design facilitates cost savings through the use of economical equipment, quick and easy installation on site, and easy service access.

Efficient noise control is vital for well-being

Noise control is an essential element of environmental protection that requires extensive knowledge and experience of industrial conditions. Valmet offers complete, guaranteed solutions for ventilation noise control, including noise surveys, sound measurements and reference point sound level calculations.

*earlier known as GreenSound BVN