Refining

Increased energy efficiency

High quality

Reliability

Leadership in Refining Performance

Backed by the industry's leading refiner technology and unmatched OEM expertise, Valmet delivers end-to-end refining solutions that are proven to optimize performance. With over 10,000 installed units globally, our vast portfolio (consisting of conical and disk refiners, and a diverse mix of refiner fillings, plates, and segments) makes up the industry's largest global installed base of refiner solutions. We continue to develop these technologies and enhance our product offering to provide the options you need to achieve performance and efficiency goals related to any and all refining applications.

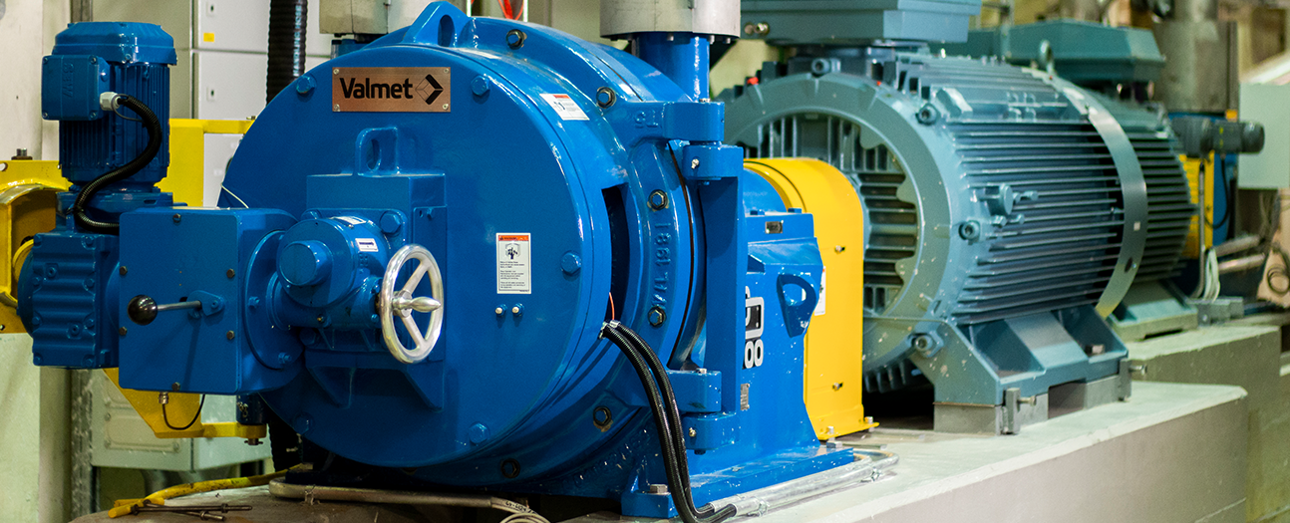

Valmet Conical Refiner Technology

The design of Valmet Conical Refiner Conflo combines the positive features and performance benefits of both refining concepts to meet the requirements of most typical short- and long-fiber refining applications, including recycled fiber treatment.

Valmet Conical Refiner Pro is a revolutionary new refining concept for low-consistency refining applications that can replace two traditional refiners and deliver electricity savings of 30%.

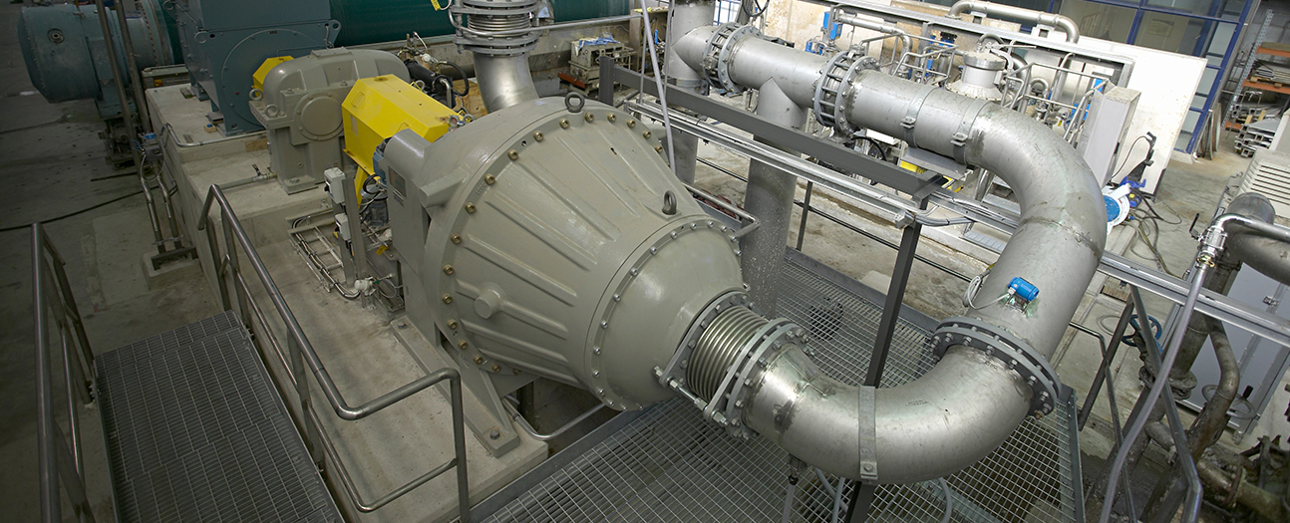

Valmet Disk Refiner Technology

Valmet Disk Refiner DD 6000 is the leading disk refiner in the industry, designed to produce stronger pulp with higher efficiency. With patented features such as its tangential inlet and splined hub technology, the DD® 6000 offers higher capacity and higher connected power than any other disk refiner in the industry.

Stronger pulp, higher efficiency

Would you like to improve your refiner capacity by up to 50%? We're here to help improve your capacity and performance and save energy.

Contact us todayA journey through refiner pilot trials and sample analysis at the Valmet Fiber Technology Center

Join Kristiina Muurimäki, Director, Pulping, Screening and Refining Technology Unit on a journey through the facility to conduct a virtual refiner pilot trial and sample analysis of your own. Click the video for a virtual tour of our Inkeroinen Pilot facility.

Related content