Instant, continuous gas temperature measurement

Valmet Acoustic Pyrometer

The Valmet Acoustic Pyrometer is a non-contact measurement system that collects highly accurate instantaneous gas temperature data in critical areas of a boiler.

Real-time temperature all the time - Reliable sound-based measurements under any conditions

Advanced software for precision analysis - Easy-to-understand data help operators make good decisions

Flexible and extendible system - Customizable and configurable to meet your exact application needs

Full-time boiler performance optimization

Continuous measurement of boiler and furnace temperature during full load is difficult yet essential. Combustion optimization is key to safety, energy conservation and emission reduction for thermal power plants.

The Valmet Acoustic Pyrometer utilizes the speed of sound to measure gas temperature. Sound waves require a medium, such as gas, to propagate, and the temperature of the medium impacts the propagation velocity.

The pyrometer generates a powerful sound wave and measures the time it takes for the wave to traverse the boiler chamber. Receivers positioned around the boiler are used to calculate the average temperature between the sound generator and receivers.

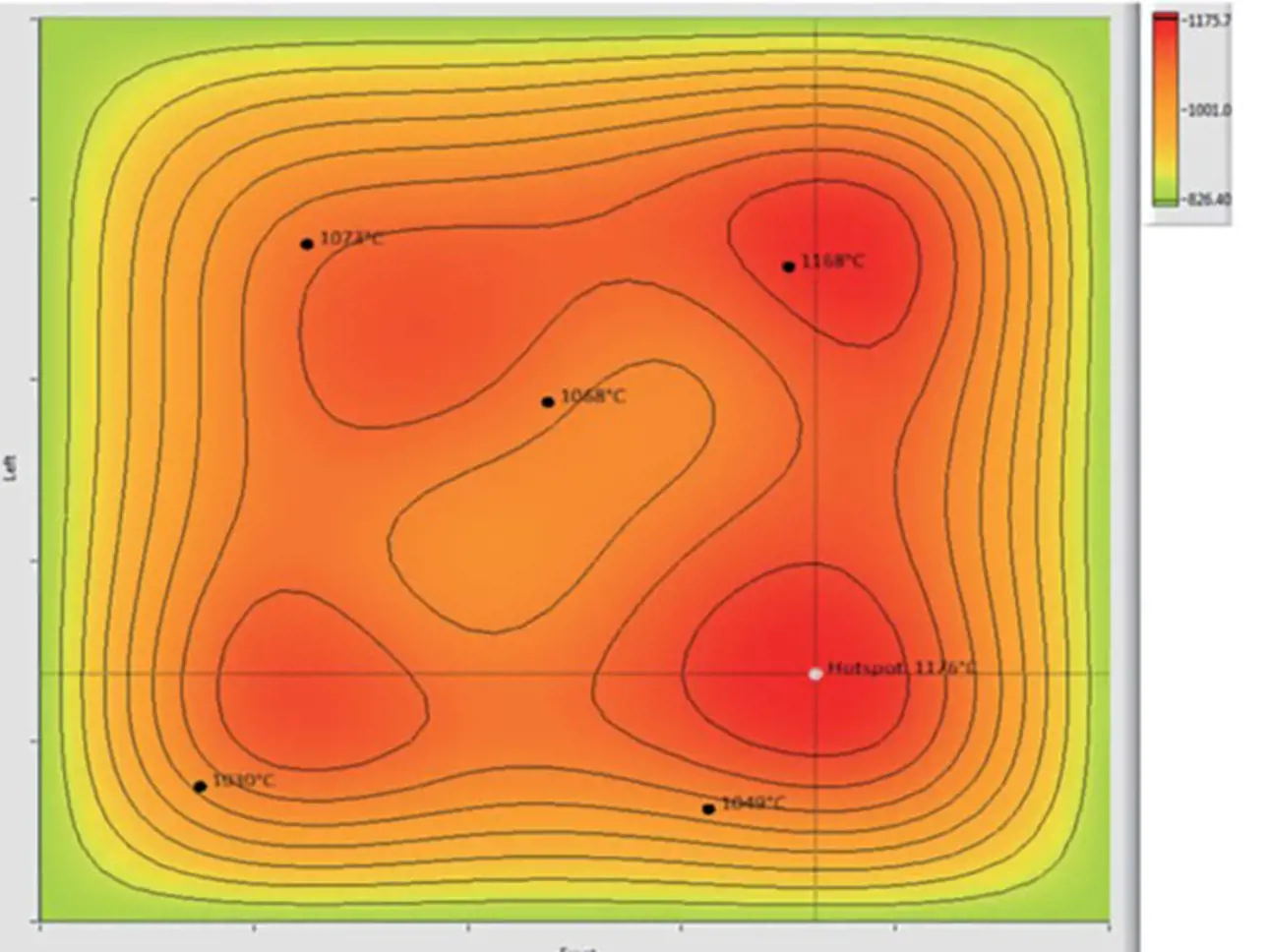

The sound wave has a sharp leading edge that is propagated concentrically from the generator for accuracy to within + 1% over a range of 0 to 1900 Celsius, even in the presence of considerable noise. The instantaneous temperature data is spatially averaged and used to create zonal temperature maps.

Easy temperature analysis with advanced software

Using the Valmet Acoustic Pyrometer, boiler operators can significantly reduce slagging, manage critical temperature profiles to aid in emissions reduction, prevent hot spots and thermal shock, as well as improve heat transfer rates.

The Valmet TempView Display software provides clean and easy to understand access to temperature measurements. Zone temperatures are automatically mapped from the boiler. This can be monitored under two dimensional, three dimensional or multiple plane views so operators can make the correct adjustments and optimize combustion conditions. The software also provides remote display, replay, hot-spot detection, and cursor temperature features.

In addition to temperature measurement, the Valmet Acoustic Pyrometer can be used for leak detection. The system constantly listens to boiler noises, measuring against preset noise thresholds and time durations, and identifies persistent sounds indicative of leaks. The system can also distinguish the sound of furnace tube leakage from other sounds (such as soot blowing) raise leakage alarms.

Create the ideal pyrometer for your needs

Valmet Acoustic Pyrometer system can be configured to meet your exact monitoring needs. Acoustic Signal Generators and Receivers can be added as desired. The signal generators can be mounted horizontally or vertically to accommodate space restrictions.

The Valmet Acoustic Pyrometer system is designed for superior reliability in hot, dirty environments. Ports are cleared by periodic air blasts and components are not sensitive to dust or dirt.

You get vital information at all load conditions to prevent excessively fast temperature rises during startup to avoid thermal stress, excessive temperatures at the reheater and during normal operation, reducing superheater coke formation. The proper flame height can be determined and possible damage caused by flame deflection reduced.

Benefits

- Significantly reduce slagging by maintaining optimal furnace flue gas temperatures

- Avoid tube damage and leaks by avoiding hot spots and thermal shock

- Improve heat transfer rate by balancing combustion

- Reduce emissions by managing critical temperature profiles

Do you want to know more?

Contact us to request for more information, quotation or an inspection trial.

Contact usRelated optimization solutions