PID tuning and process control services

Your reliability partner

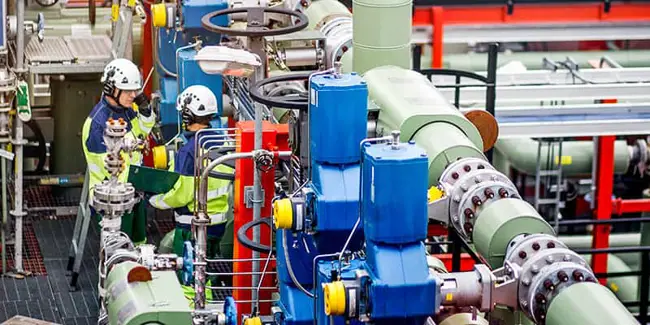

In a typical plant, many controls and processes are not operating optimally, which can result in less stable production, higher raw material usage, increased energy consumption and lower yield. Valmet PID tuning and process control services (formerly Expertune) are designed to identify controls impacting performance and help you return to optimal production.

Hidden PID tuning and performance issues are costing you money

A typical process plant is losing millions annually from poorly-performing control systems. Generally, about 20-30% of controls are in manual mode, and up to 85% of control loops have sub-optimal settings.

Furthermore, 20-40% of controllers are oscillating, adding to plant variability, and hurting reliability. With so many issues, it can be hard to monitor, prioritize, and resolve process problems.

Our control performance experts can provide solutions to these problems.

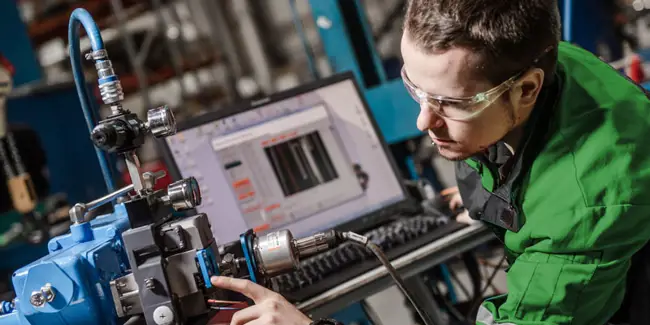

Our PID tuning and process control services identify incorrectly configured control loops, root causes of issues, and prepare corrective actions that optimize your control performance. To get started you can read the PID Tuning tutorial.

PlantTriage

PlantTriage is a loop optimization software that continually monitors your plant to identify issues whenever they occur.

Allowing PID tuning and much more, this award-winning software was designed and developed by a team with hundreds of years of control experience.

Global Loop Optimizer SaaS

Global Loop Optimizer SaaS delivers safe, world-class PID loop tuning to every plant in your company. It is an optimal software if you have multiple plants and more than 100 loops to tune.

PID Loop Optimizer

PID Loop Optimizer is a PID tuning software especially for single plants and locations with 100 loops or less to tune.

With PID Loop Optimizer you can eliminate guesswork and stabilize your plant quickly.

Control performance service

Control performance service is a turn-key solution to plant performance problems and issues with poorly performing control systems.

Control performance evaluation

Our control performance evaluation provides an expert assessment of your process controls, giving an overall picture of problem areas as well as their impact on production costs and volume.