Infrared camera solutions for combustion management

Valmet Furnace Imaging System, IR

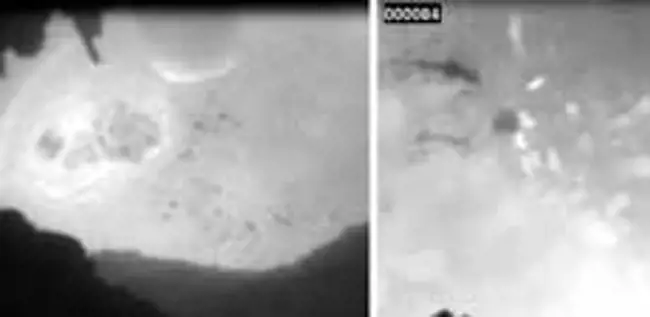

The Valmet Furnace Imaging System, IR provides online visual analysis using infrared light. With a clear view through dust and gas, operators can monitor developments anywhere in the combustion chamber.

Unobstructed visual observation - Infrared waves generate clear images from the entire combustion area

Dual-purpose camera - Same camera module works in both mobile and fixed installations

Complete software application suite - Custom-built software for advanced image and data analysis

Infrared imaging for extreme conditions

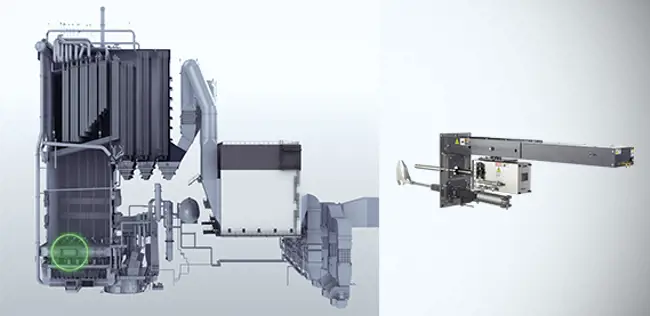

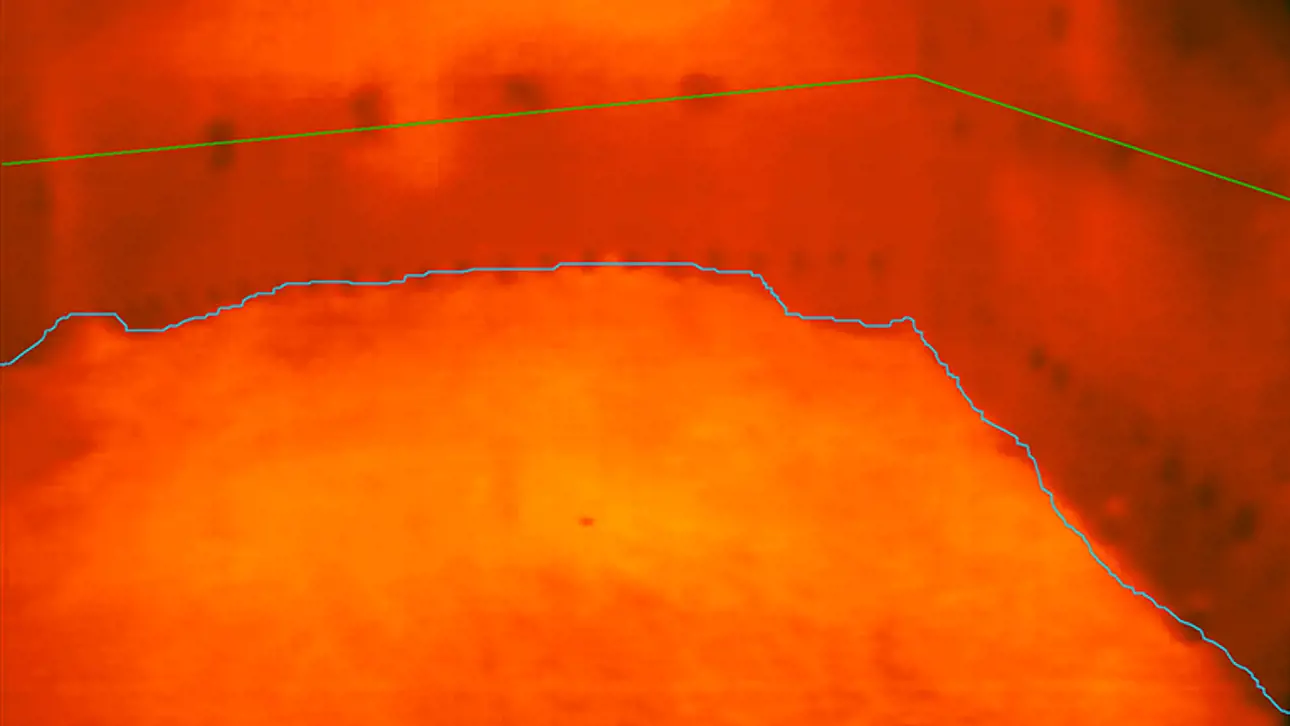

The Valmet Furnace Imaging System, IR provides real-time data to identify problems and take corrective actions. The infrared camera can see through flue gas and fly ash at temperatures of 370°C to 1900°C. The quality and depth of view from infrared imaging enables comprehensive observation and analysis at full load to reduce risks and improve productivity.

The Valmet Furnace Imaging System, IR aids in visual observation inside the furnace environment, providing information about slag buildup, burner operation, flame position, and heat exchanger tube plugging. This helps improve heat transfer efficiency, reduce maintenance costs and contributes to higher availability.

The system is specially designed for use in extreme, high-temperature processes, and is engineered for durability and longevity. For pulp and paper recovery and power boilers, the infrared system aids in visual observation of boiler environments, providing information about bed conditions, water leaks, liquor-spray patterns, and sootblower operation. We also offer a unique configuration to support Ladle Metallurgy Furnaces, providing an unobstructed view of the entire tapping process.

Fixed and mobile inspection

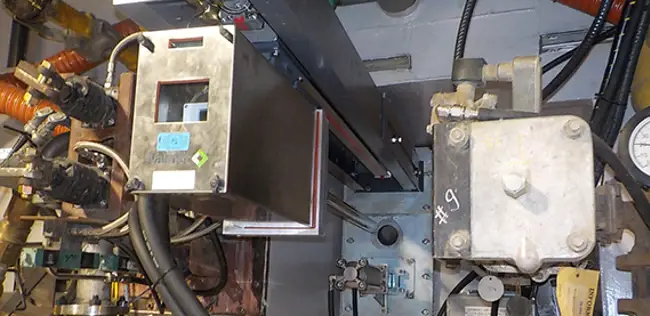

The infrared camera of the Valmet Furnace Imaging System, IR features a dual-use module design. The same camera can be used in a fixed installation for mobile inspections.

The Fixed Mount Mid-IR installation can be a single camera or an array of cameras for full coverage of the combustion environment. A fixed installation includes the infrared camera, air-cooled electrical enclosure, straight lens tubes of varying length and view angles, along with optional automatic retractor for lens protection and port rodder for cleaning.

The infrared camera can be removed from fixed installation and used with a mobility kit for inspections at any accessible boiler port on an as-needed and when-needed basis.

The Portable Mid-IR mobile inspection camera kit contains everything you need to inspect a boiler from any accessible port. The mobility kit is housed in a single wheeled case and includes an air filter and connection hose, rechargeable batteries and charger, and a heat shield to protect the user. The kit can be used for internal boiler checks and for inspecting shell or electrical equipment.

Advanced analysis with purpose-built software

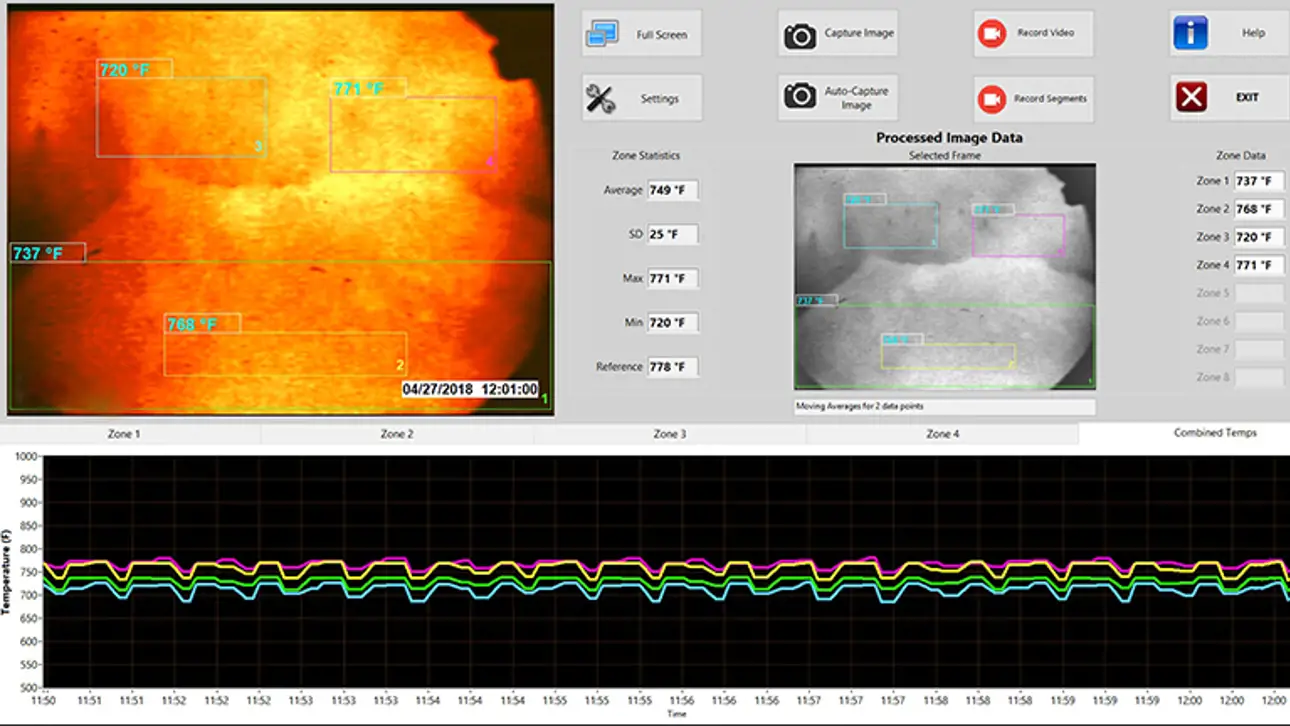

The Valmet Furnace Image Processing Suite take visual and temperature data to a whole new level of value. The Valmet Basic Viewer offers a simple interface for viewing and recording digital video streams. With image colorization, time and label overlays, the ability to draw and mark live images, and much more, this software is packed with useful features.

The Reporting and Analytics software application gives operators unparallel insights into their data. For instance, you can compress an entire day of data into a short video with key metrics, making it easy to check and understand the events of the day. Reports can also be distributed automatically.

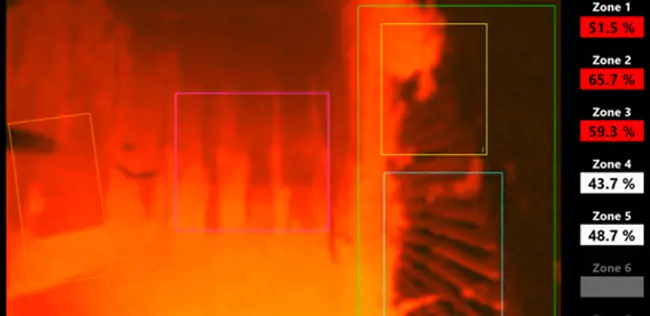

The key to achieving the greatest accuracy and efficiency of your boiler cleaning is to improve input quality. Whether sequenced, timed or managed by an intelligent soot blowing system, the Slag Indexing software application provides an innovative additional layer of control.

Thermal data with visual inspection

In addition to providing clear visual images, the Valmet Fixed Mount Mid-IR/Thermal configuration option uses a through-the-lens pyrometer that measures temperatures from 530°C to 1600°C in real-time to within 5°C. Using advanced analysis of temperature and imaging data, operators can assess various operational features and conditions.

With the Mid-IR/Thermal configuration, you can use the Infrared Thermal Viewer software application. It provides the most advanced integrated imaging and temperature measurement capability for critical boiler areas. With accurate real-time temperature readings, you can enhance efficiency in superheated areas, waterwall conditions and bed temperatures.

|

Pulp & Paper benefits |

Power utility benefits |

Metallurgy benefits |

|

|

|

Do you want to know more?

Contact us to request for more information, quotation or an inspection trial.

Contact us