Automated online dirt and brightness analysis

Valmet Dirt Count Analyzer - Valmet DCD

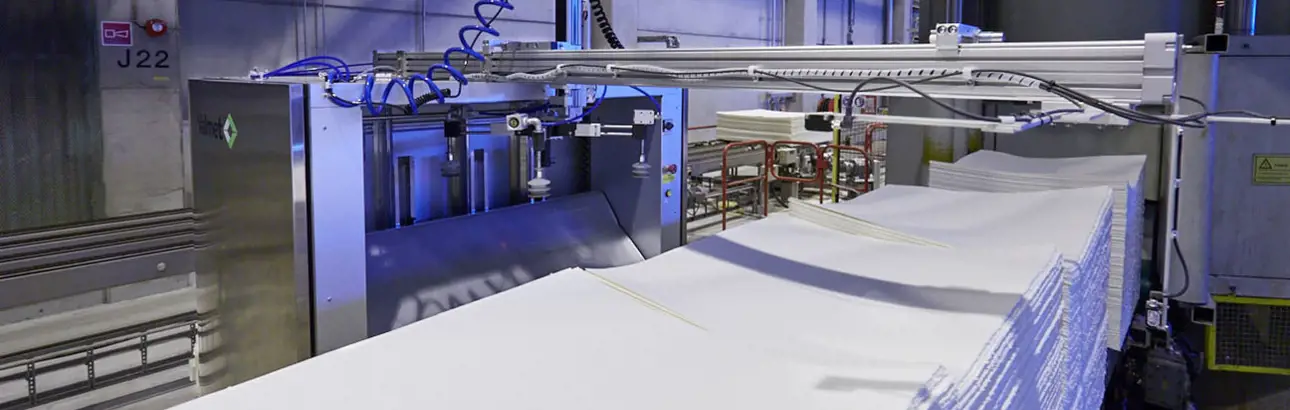

The Valmet Dirt Count Analyzer (Valmet DCD) is a fully automatic measurement system to control the quality of pulp sheets. Operating independently 24/7 next to the baling line, the Valmet DCD consistently and accurately measures up to 12 sample sheets per hour.

Real-time quality analysis for best quality at the best price

Most accurate analysis on the market of dirt and brightness for any pulp type

Easily integrate to other mill systems for complete quality control

Best price with efficient pulp grade certification

Dirt count and brightness are pivotal indicators of end product quality. With the Valmet DCD, you can continuously analyze dirt and brightness, with optional color measurements also available. Precise data enables fast response to quality trends.

When a pulp dryer starts up after shutdown, there is typically a lot of dirt at first. A great opportunity for optimization is to know exactly when the pulp quality has improved enough to comply with customer specifications. Washing water used at startup can also be minimized.

Environmental and economic demands are driving rapid change in pulping technology. The complexities of the process and the speed of production leave little room for error or time for lab tests. The Valmet DCD gives you the facts you need for pulp grade certificates, ensuring the best quality at the best price.

Best quality with complete dirt and brightness analysis

The Valmet DCD takes samples according to a timer you can adjust to your specific baling line operation. Sample sheets are automatically pulled off the baling line just before weighing and packing. If needed, you can also manually feed in sample cheats to the analyzer.

The Valmet DCD supports both dry and wet testing methods. You can configure the analyzer to run dry, wet, or even both test methods for the same sheet sample.

Two camera arrays systematically scan the sheet from both sides for dirt specs. The dirt count is classified based on size and shape according to the classes you select in the analyzer configuration.

At the same time, the brightness tester measures the brightness from different points of the sheet and calculates an average value. The Valmet DCD uses a blue LED for low contrast detection to ensure accurate results regardless of pulp type. An optional color measurement using TAPPI standard T 422 can be added to the solution.

Get reliable sheet quality data in real time

Dirt count and brightness are essential properties that determine the quality of pulp, but manual laboratory tests are labor intensive and to slow for day-to-day mill operations. Valmet DCD provides accurate, high frequency data in real-time to the mill’s information and quality management system.

Measurement results are stored locally in the Valmet DCD, where there is enough memory for at least a year’s worth of data. The results can also be sent to other information systems, such as the bale tracking system like the Valmet DNA Bale Quality Management solution.

In addition, up to four days’ worth of processed images are stored locally. For longer dirt tracking history, you can set up the Valmet DCD to transfer images to an external storage location.

The Valmet DCD is not only effective, but also very reliable. Only a quick cleaning is needed every couple of weeks to keep it running in top form. This ensures the analysis is consistent and easily trackable so laboratories can independently confirm measurements.

Downloads |

||

|---|---|---|

| Valmet Dirt Count Analyzer Brochure | ||

Related solutions