Field Services for board and paper makers

On-site and remote field services with high-level standards for safety and work quality for your machinery. Our target is to help you keep your machinery in the optimal condition for the best performance, so you can concentrate on your business goals.

We can serve you both locally and remotely

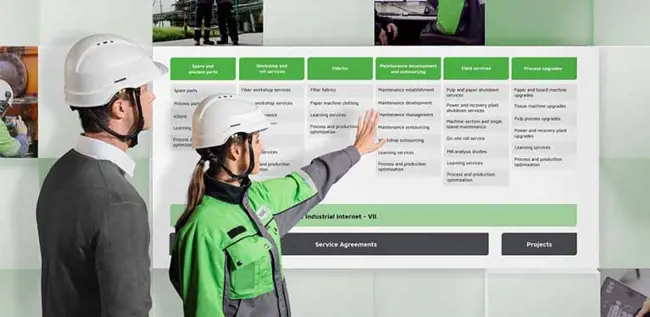

We plan, execute, manage, and develop maintenance activities according to your needs. Trust is earned every day. Our on-site and remote field service offering consists of:

- Maintenance and process supporting services

- Annual shutdowns

- Maintenance shutdowns

- Daily maintenance

- Remote services

Remote field services

At Valmet, we are continuously developing our field services by strengthening our local and global presence, developing our products and services, improving our field service professionals’ competences, and enhancing our digital platforms for an improved customer experience.

Our target is to help you keep your pulp mill in the optimal condition for the best performance, so you can concentrate on your business goals.

Using the remote field service possibilities is an easy and safe way to get the process, automation and maintenance expertise & support you need, through our local service center or even without a site visit.

Board and Paper Field Services Handbook

Prevent unexpected failures and find guidance and recomendations for board and paper machine maintenance.

DownloadCome along for a 11 day shutdown at Klabin Monte Alegre paper mill

Valmet and Klabin’s Monte Alegre paper mill continued their successful nine-year annual maintenance shutdown cooperation in 2019. The shared values of safety, sustainability, quality and respect for others have taken Klabin and Valmet a long way forward.

Do you need maintenance or support for machinery or process performance development?

Whether it’s a survey, maintenance, shutdown management or a full maintenance, don’t hesitate to contact your closest Valmet Service Center for guidance.

Contact usLong-term collaboration enables cost planning, predictability, and efficiency

Valmet can help in the planning and optimization of your operations for maximum profitability and optimum production efficiency. We can provide solutions tailored to your needs that are cost-efficient, reduce downtime and secure availability. A service agreement provides more consistent and efficient maintenance services that are tailored to each specific mill and culture to maximize your maintenance and production efficiency. The agreements may include field services, studies, upgrades, process development and maintenance management programs.

We have machine-wide services for your board and paper machines

Our Field Services offer consists of a comprehensive range of services to enhance the board and paper machines' efficiency and reliability. Tail threading and doctoring are machine section-specific services that focus on improving the performance of specific sections of your machine. Machine-wide services like production line and vibration study are focused on improving the performance of your entire machine. Our goal is to help you optimize your machine's performance to the maximum level, improving productivity, reducing waste, and increasing profitability.

Stock preparation field services

Proper and regular maintenance of the equipment in the stock preparation and approach flow systems of a paper or board machine is crucial to ensure optimal performance and productivity. Specifically, maintenance of refiners, pulpers, and machine screens is essential to achieve the highest possible utilization rate and reliable operation, while minimizing the risk of unplanned shutdowns. By regular maintenance you can prevent equipment failures, reduce downtime, and avoid costly repairs. This not only improves productivity but also increases profitability by reducing waste and improving product quality.

Click to discover our full field services offering for stock preparation

Headbox field services

Good headbox condition is essential for maintaining the quality and consistency of the final product. The headbox is a critical component of the machine that controls the flow and distribution of the pulp onto the forming fabric. If the headbox is not functioning properly, it can lead to a range of issues, sheet streaks, basis weight variations, and formation, that can impact the quality and consistency of the paper or board produced. We offer services such as cleaning the slice lip, audits, and apron reconditioning, headbox seals replacement, and MX06 coating for optimal performance.

Click to discover our full field services offering for the headbox

Forming section field services

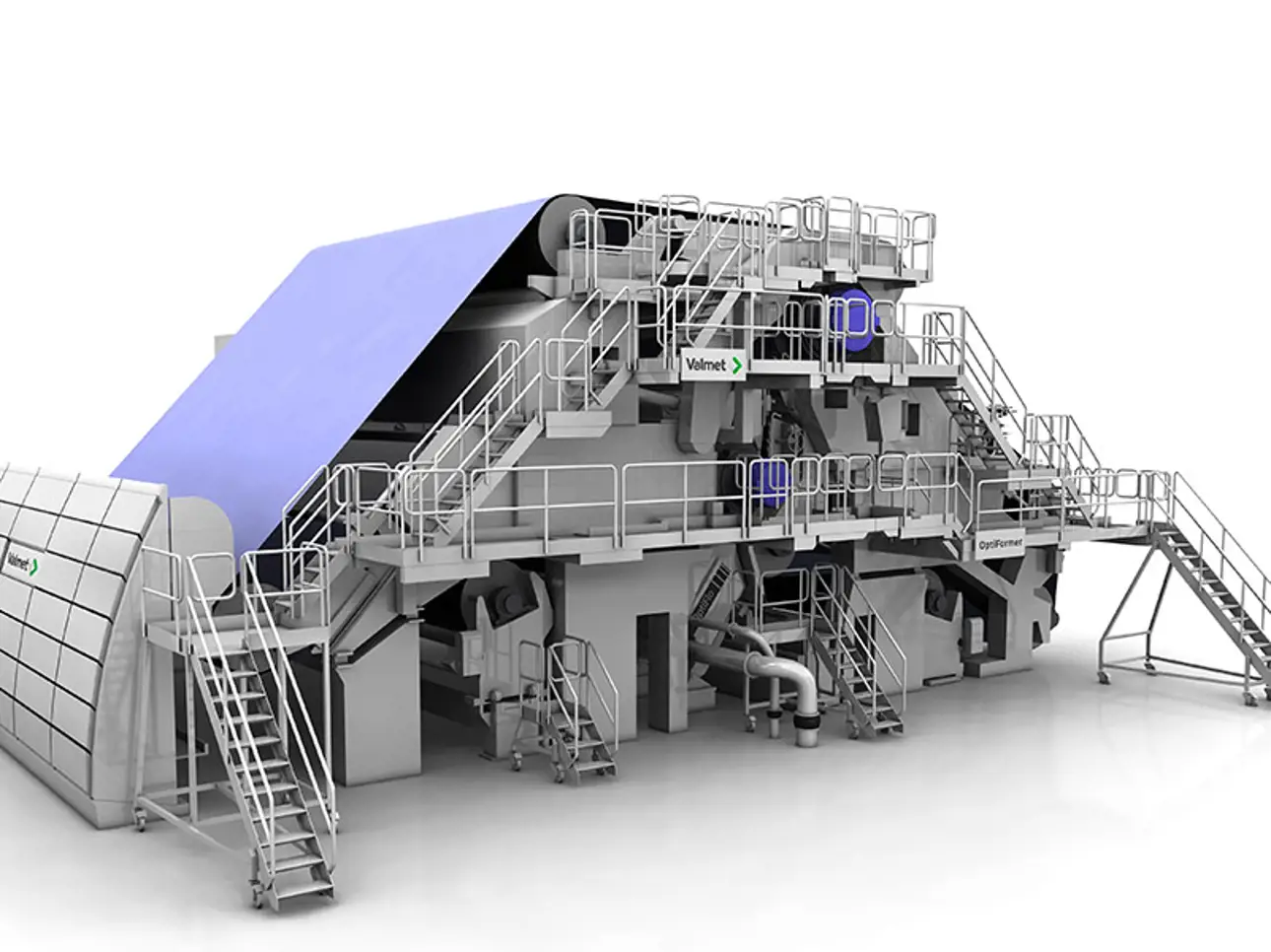

Servicing the forming section is critical to maintaining the quality and consistency of the final product. Regular maintenance of the forming section can help to prevent issues like sheet streaks, poor formation, and variations in the basis weight of the paper or board. We offer field services like vacuum system study, mechanical audit, breast roll shaker services and fabric insertion unit (FIU) services to ensure the reliable, safe, and efficient operation of the forming section.

Click to discover our full field services offering for the forming section

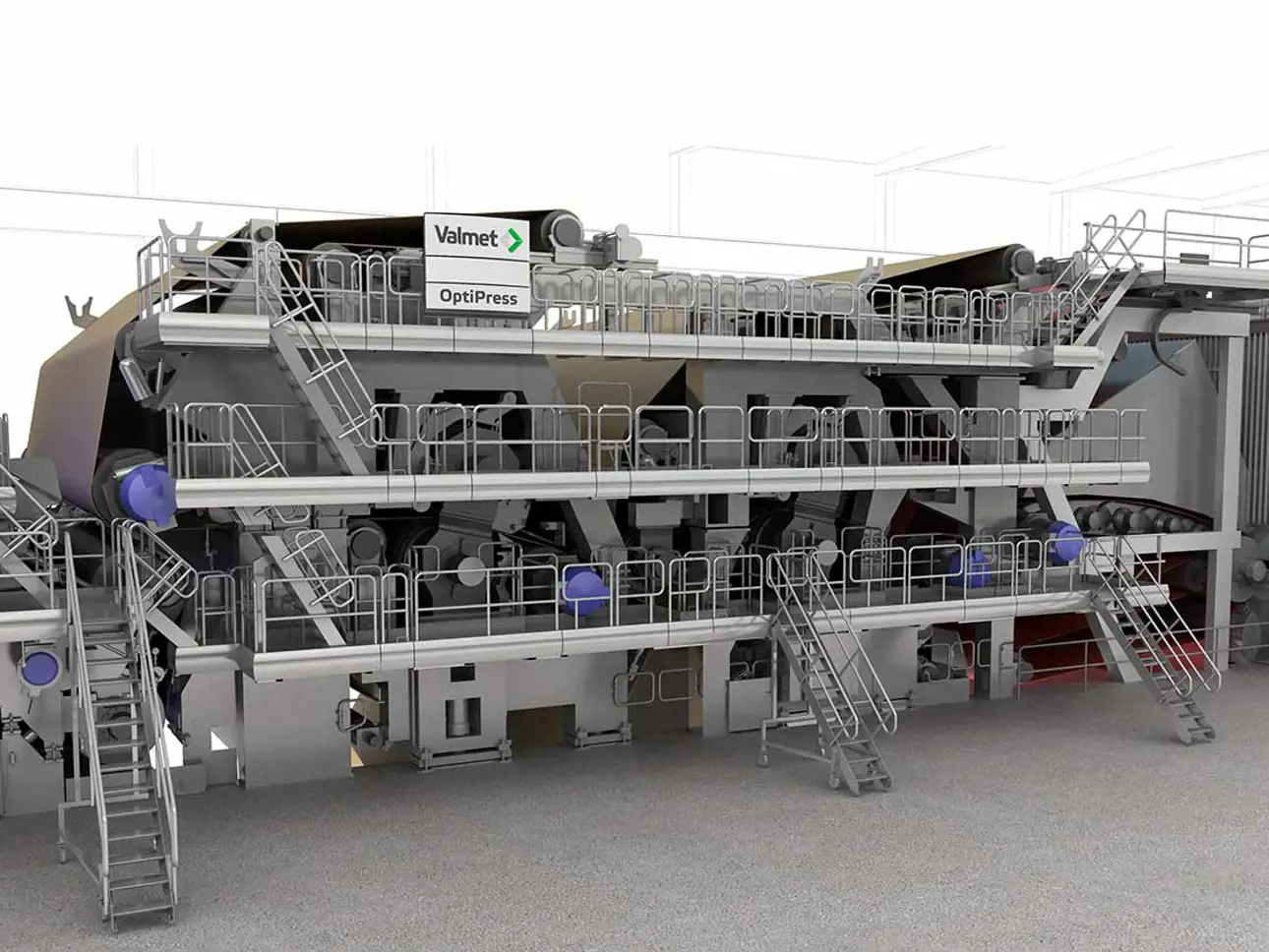

Press section field services

The reliability and functionality of the press and press rolls are crucial factors in maximizing the performance of your paper or board machine. Regular maintenance of the press section can prevent sheet breaks, web wrinkles, and poor sheet quality. We offer a comprehensive range of services, including nip profile measurements, on-site roll servicing, steam box servicing, and audits such as shoe press mechanical and hydraulic audits. Our services and improvements are designed to enable the components of the rolls and presses to operate optimally without interruption.

Click to discover our full field services offering for the press section

Dryer section fields services

Servicing the dryer section is critical to maintaining the quality and consistency of the final product and maximizing the efficiency and productivity of the production process. Regular services can help to prevent sheet breaks, web wrinkles, and poor sheet quality. We offer services for web stabilizers, hood, heat recovery and studies for steam and condensate system, dryer cylinder safety and performance and much more.

Click to discover our full maintenance offering for the dryer section

Sizer and coater field services

The good condition of the sizer, coater, and machine circulation is essential for the good runnability of the paper machine. It can help to prevent issues such as streaks, coating defects, and uneven paper thickness. Our expertise in the sizing and coating process, automation, and mechanical maintenance, as well as in blades, rods, rolls, and raw materials, can improve your machine’s performance.

Click to discover our full filed service offering for sizer and coater

Calender field services

The typical calendering models are hard nip, soft nip, multinip, and metal belt calenders. Regular service of the calendering area in paper and board mills is essential to ensure optimal performance and to prevent issues such as poor paper quality, sheet breaks, and equipment failure. The process is a complex combination of mechanical, automation, hydraulic, and process expertise, and requires specialized knowledge and skills to operate and maintain effectively. Roll-related expertise is also needed, whether it concerns the thermo roll, polymer roll, or deflection-compensated roll. We have talented specialists for each area of expertise, which means we can offer every kind of calender service.

Click to discover more maintenance services for the calender

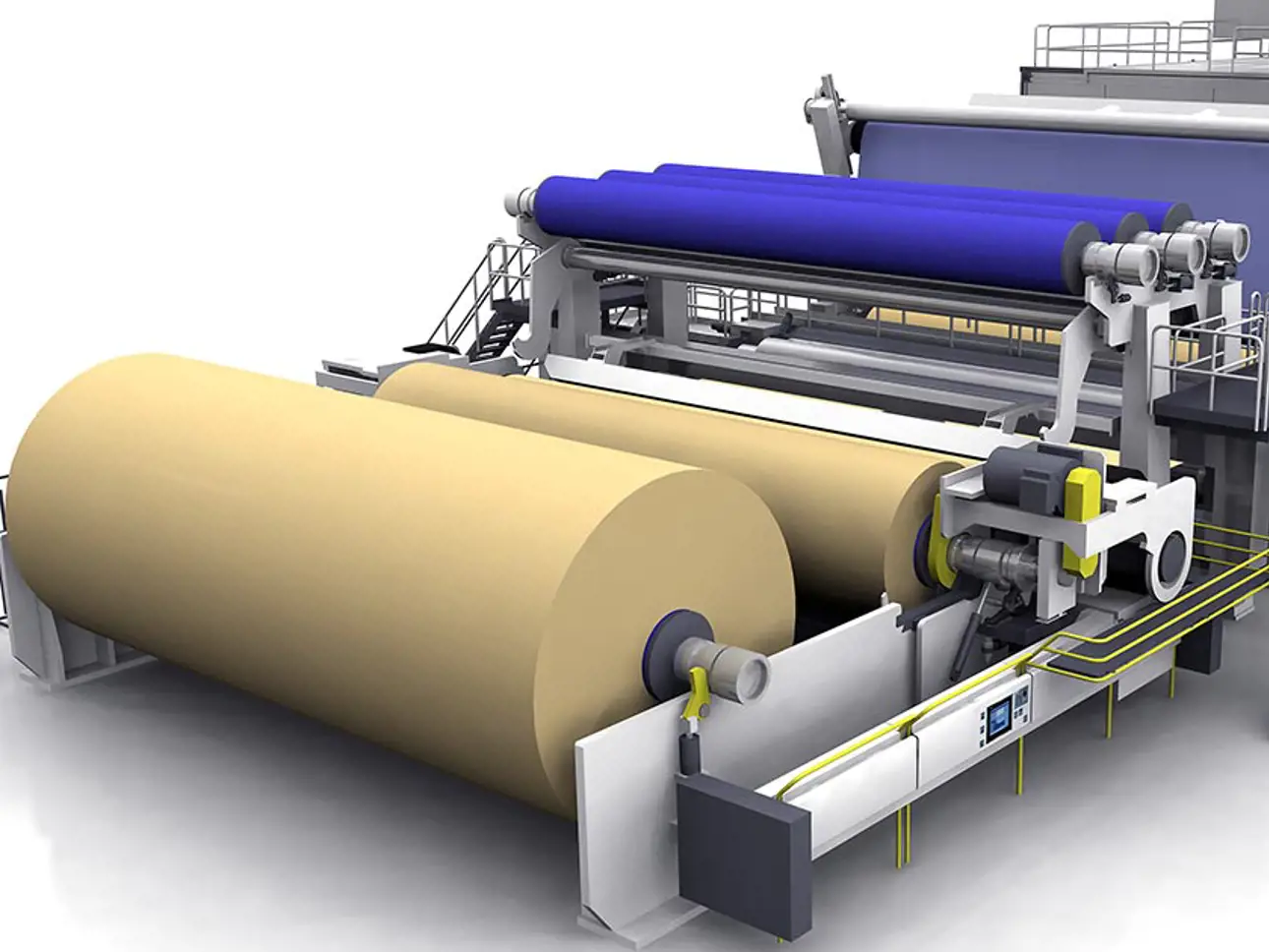

Reeling field services

The regular servicing of the reeling area is essential to ensure optimal performance and prevent issues such as sheet breaks, wrinkling, and uneven winding. By servicing the reeling area regularly, identifying and addressing roll defects, bearing wear, and mechanical issues can improve performance and reliability. Valmet's reeling field services provide information about the reel's condition and maintenance recommendations for short- and long-term improvements.

Click to discover our full field services for reeling

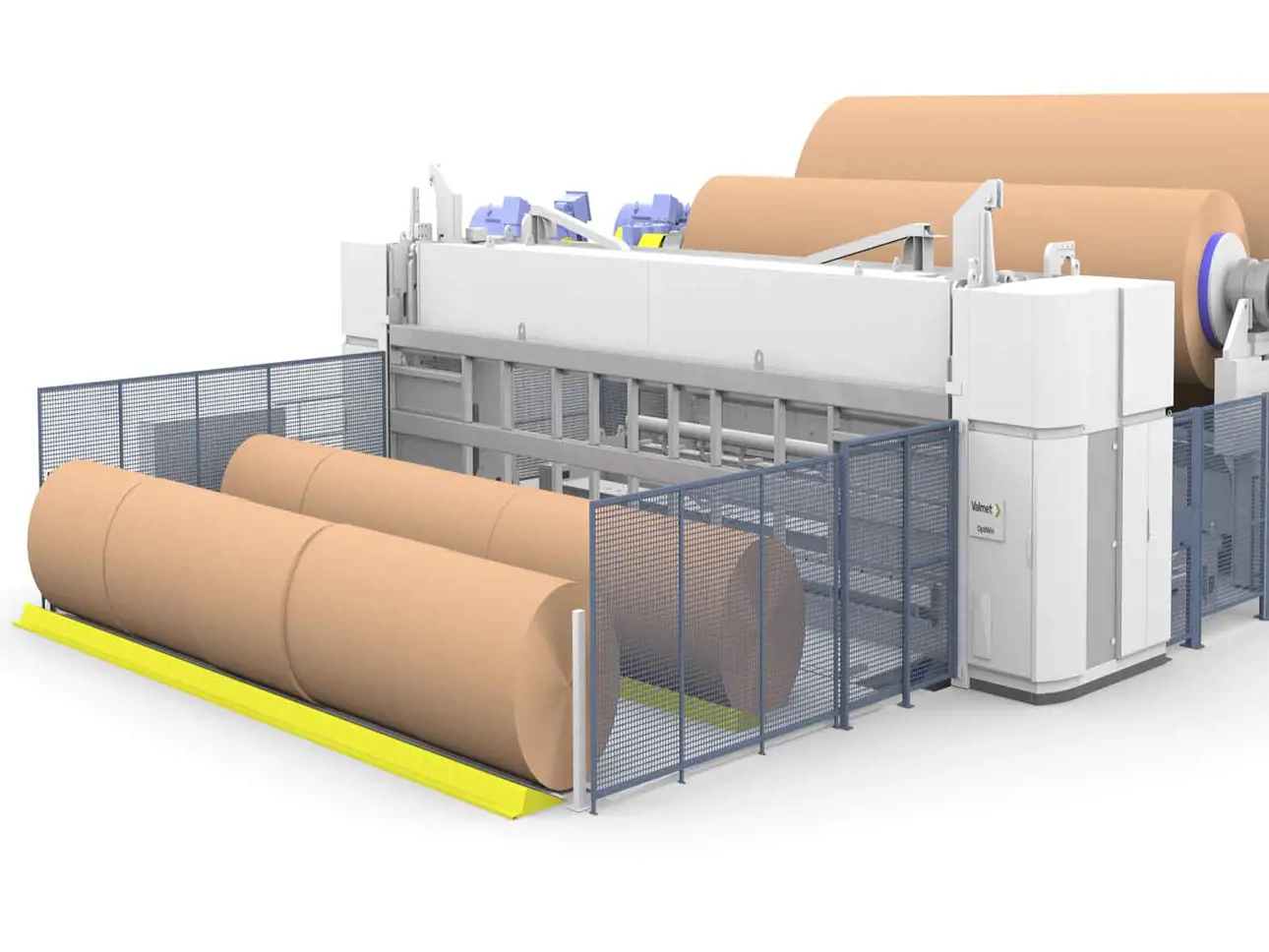

Winder field services

The winder is the final equipment in the paper and board making line that produces the final customer rolls for sale. The quality of the customer rolls and the smooth and well-functioning operation of the winder are crucial for the customer's production figures and the capacity of the entire plant. Regular servicing is necessary to prevent issues such as web breaks, uneven winding, and sheet damage. We offer numerous services for slitter devices, sectional roll, belt exchange, workshop, as well as audits for capacity and safety.

Explore other maintenance and repair services for board and paper machines