Roll covers for tissue production

Increased production efficiency with Valmet’s roll covers

Valmet’s long experience in tissue making processes help you to choose the right roll cover for each tissue machine application. Our roll covers and coatings are based on state-of-the-art polymer and thermal coating technologies that provide excellent wear resistance, stable roughness and hardness, and durability in demanding operating environments, enabling trouble-free run periods.

Up to 50% longer running interval

Optimal tissue quality

Improved dewatering capability

5% energy savings

The right roll cover solution for each tissue process condition

At Valmet, we are constantly working to develop the essential press properties of a roll cover, such as durability, reliability and dewatering capability. Our comprehensive product offering of both polyurethane and rubber covers for press applications based on hundreds of tissue machine deliveries clearly demonstrates our successful results.

Not only offering high perfoming roll covers, we also provide tools for increasing post-press dry content, resulting in savings in drying energy, without sacrificing bulk.

Want to talk to our roll service experts?

Answer a few questions and our roll experts will contact you shortly.

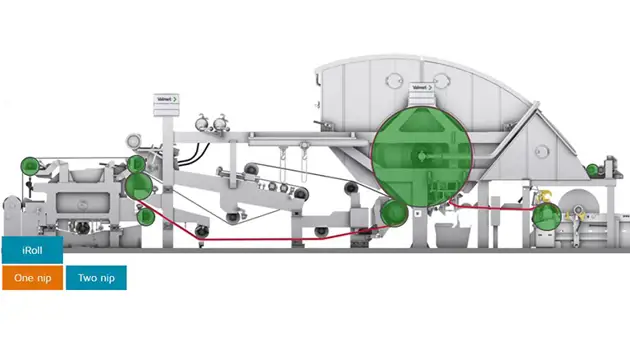

Contact usBest tissue profiles with right roll covers and iRoll technology

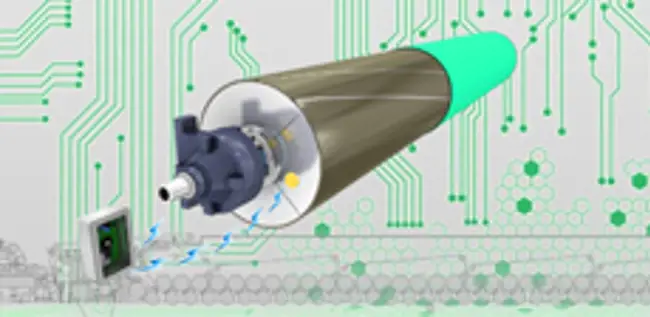

Press roll covers, in particular, play a significant role in tissue machines. In tissue pressing, nip pressure profiles also often impose extra challenges on efficiency and product quality. Valmet's iRoll tehchnology offers excellent tools to measure, analyze and optimize nip pressure profiles in tissue machines.

Optimizing roll cover material, hardness and topography, as well as combining it with an optimized nip pressure profile, will let tissue makers benefit form the best tissue profiles, improved productivity and better energy efficiency.

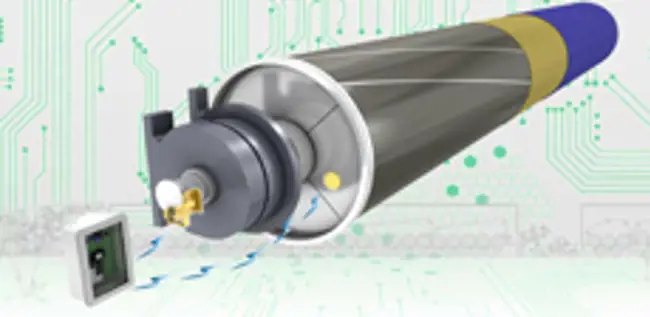

Optimized Yankee performance with Valmet Infinicote Yankee Metallizing

Valmet Infinikote Yankee Metallizing is the most reliable Yankee thermal coating available, providing superior heat transfer, extended doctor blade life and longer run times. It is also highly corrosion-resistant.

Explore our roll cover products from interactive demo.

By exploring this roll cover application tool you can easily see different cover options for your tissue machine.

Start exploringClose to you through 26 roll service centers

Our global roll workshop network around the world ensures professionals can easily carry out roll cover inspections; perform onsite coating, patching and repair services; and provide application support and general troubleshooting in your location. We also offer support ranging from grinding, recovering, and servicing rolls, to complete roll service management

A more sustainable future with a new generation of roll cover materials

A major part of the raw materials used in roll covers – polymers, resins and other industrial chemicals – has traditionally been manufactured from fossil-based raw materials, and refined and processed from crude oil. Valmet is now taking a giant leap toward a more holistic approach with a focus on sustainability, aiming to replace as many of the roll cover raw materials as possible with more sustainable alternatives. The target is to use recycled materials and renewable resources, and more broadly to save energy.

Using recycled consumer plastic or glass as the reinforcing fiber or filler in composite roll covers, or bio-based resin and hardener in the polymer matrix, are good examples. What are the benefits of bio-based materials?

“They remove the dependency on crude oil,” states Dr. Jani Turunen from Valmet. He continues: “We only approve renewable materials derived from non-food chain plants or plant parts, meaning their use does not affect global food production. Cultivation and harvesting of plants must not endanger the growth of natural forests either. In the best cases, bio-based materials can be produced from plant parts that would otherwise be waste. Lignin, carbon black made of lignin and nanocellulose are good examples, and all three can be utilized as reinforcing fillers in roll covers.”

Articles and references

keyboard_arrow_leftBack

{{currentHeading}}

{{productForm.Name}} {{"("+productForm.Size+")"}}