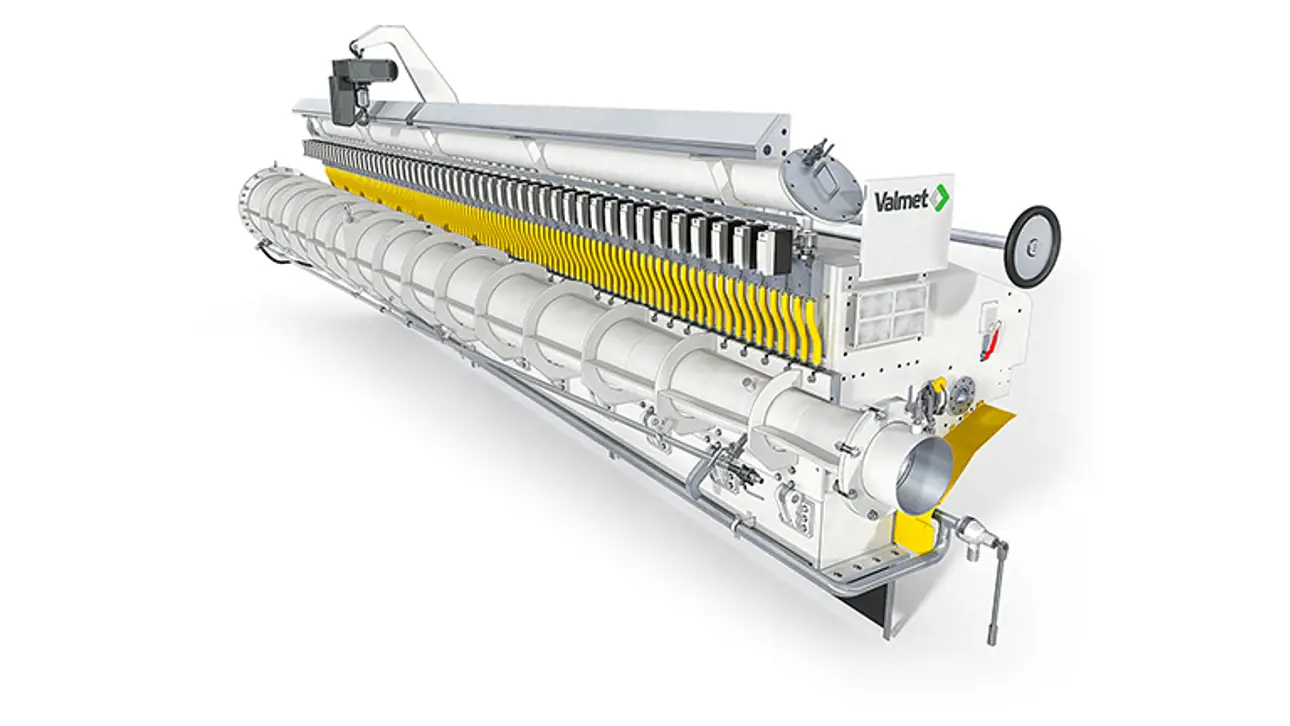

Valmet Headbox

One of the most important parts of a pulp drying machine is the headbox. The modern wet end features an advanced dilution controlled hydraulic headbox, which ensures an excellent web profile both in cross and machine directions.

Uniform basis weight

Good formation

Large range of stock flows and consistencies

Stainless steel design

Stable, rigid design allowing high stock temperatures

Complete preassembly

For special grades, one alternative is a rectifier roll headbox, which can be run either over or under-pressurized to obtain the correct slice flow. This also provides good formation, small basis weight variation and efficient pulsation dampening in wide flow and consistency ranges.

The headboxes are constructed of stainless steel and the frame is very rigid, tolerating high-stock temperatures. All the surfaces exposed to stock are polished to the required surface finish. For easy service, the manifold can be turned down for maintenance.

Web profile control

Valmets’s automation solutions for various headbox types cover manual, remote as well as fully automated web-profile controls. The most advanced automation solutions offer sophisticated methods for both machine direction and cross direction profile control. Web profiles are controlled with IQ Dilution Profiler/IQ Slice Profiler using measurement from Valmet IQ Quality Control System. Read more about Valmet IQ Quality Control System

Our expertise is at your service

We at Valmet are committed to moving our customers performance forward and ensure smooth, disruption-free operation, supporting you all the way.

Contact us