Efficient peroxide bleaching of high yield pulps

Valmet has focused on bleaching research and development for more than 50 years and has become the leading supplier of environment-friendly pulping processes.

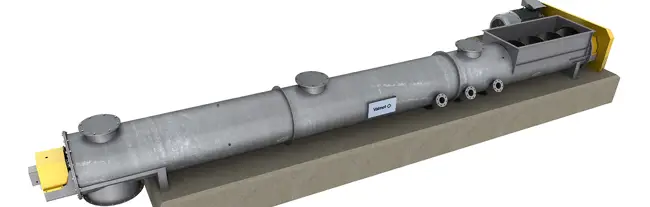

In mechanical pulping, Valmet has extensive experience of peroxide bleaching processes for all types of mechanical pulps - TMP, CTMP and PGW. Backed by this experience, our mechanical pulp bleaching systems represent an investment in proven process know-how and long-term support.

Mechanical pulps retain most of the lignin, cellulose and hemicellulose present in the wood used to make the pulps. It would be impractical to remove this much lignin by bleaching, and undesirable since one of the big advantages of mechanical pulp is the high yield of pulp based on the wood used. Therefore the objective of bleaching mechanical pulp (also referred to as brightening) is to remove only the chromophores (color-causing groups). This is possible because the structures responsible for color are also more susceptible to oxidation or reduction.

Our expertise is at your service

Our focus is to bring your performance forward. Get in touch with us through our website, or through your local Valmet office.

Contact uskeyboard_arrow_leftBack

{{currentHeading}}

{{productForm.Name}} {{"("+productForm.Size+")"}}