Screen baskets & rotors for pulp producers

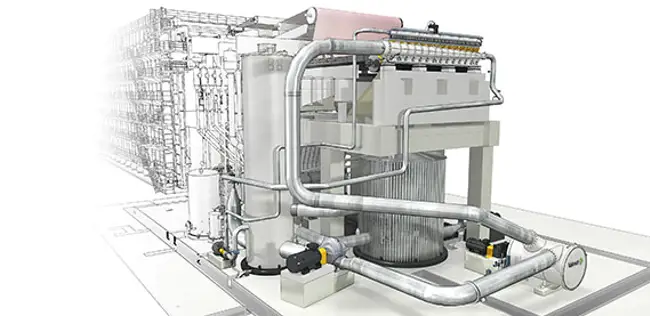

Stable screening room with high-quality process parts

Pulp quality together with screening and energy efficiency are the key components guiding our screen basket development for cooking and fiberline, pulp drying and mechanical pulping processes.

Pulp quality

High cleaning efficiency

Improved runnability

Energy savings

In Valmet screen basket family you find the right basket for all your needs. The full range of tailor-made baskets combined with performance agreement, technical support services and close co-operation is helping you in optimizing the production performance for years to come. By choosing Valmet as your screening technology supplier, you will gain the benefits of Valmet's in-depth knowledge of the industry. We consider ourselves as a partner in your efforts to optimize the performance of your screening, in all positions.

Screening requirements for high-end pulp quality

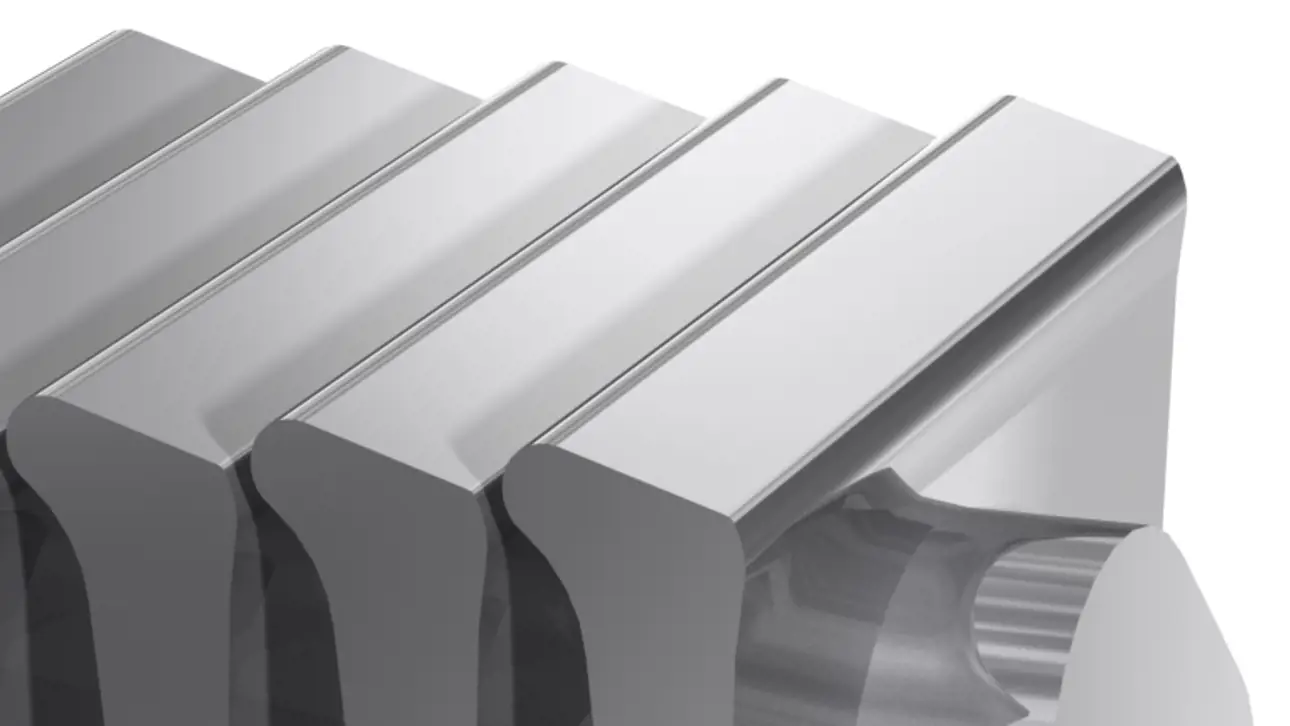

Typical screening pulp quality objectives are low freeness drop, excellent shives removal and fiber fractionation. At the same time, the maximum production capacity needs to be achieved with the lowest energy possible. Valmet’s non-welded wedge wire screen baskets’ high slot accuracy and durability combined with ideal rotor foil shapes are a must for starting the breakdown challenge in step-by-step process improvements.

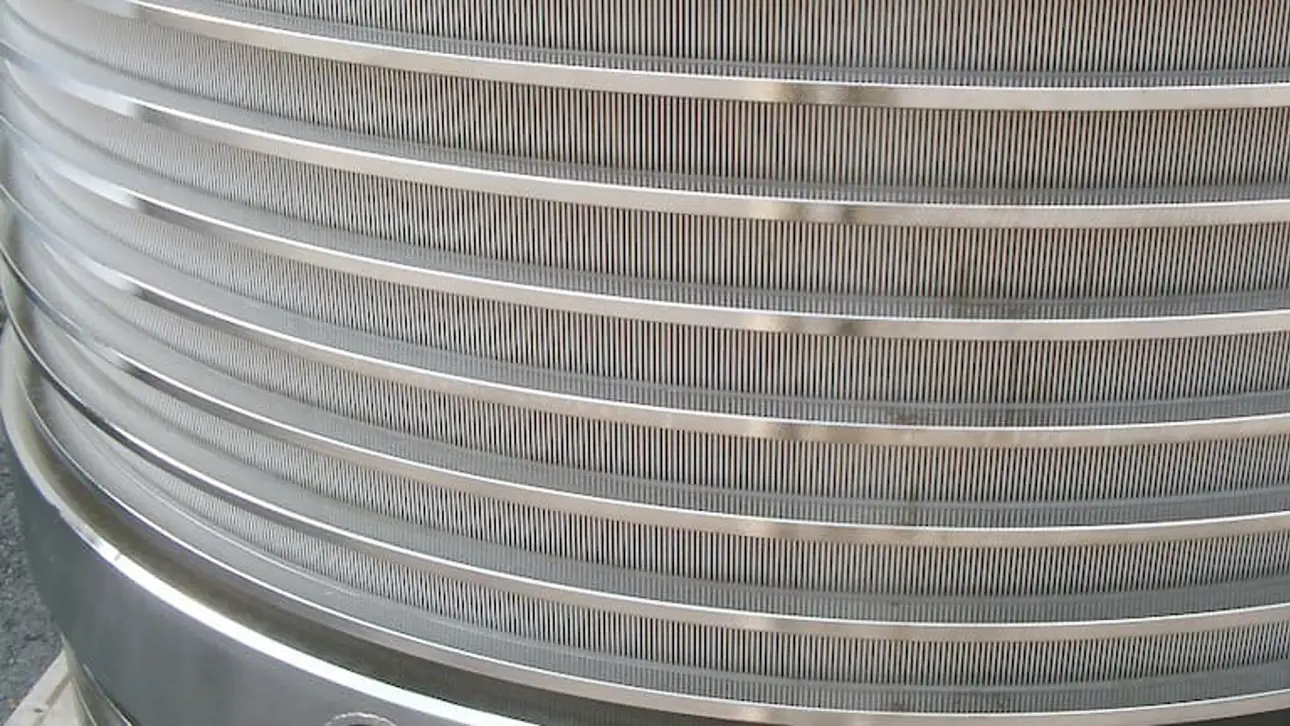

Screen Basket ML

Durable structure for low- to medium-consistency applications. Industry-proven wire-clamping technology, laser cut precision and a wide range of wire shapes.

High open area between retaining rings reduces flow resistance, so high flow capacity is achieved. Non-welded construction ensures accurate slot width for excellent shives removal efficiency over a long lifetime.

More than 50 baskets delivered to BCTMP and TMP applications.

Screen Basket NS

Robust structure for the most demanding high-consistency applications. Industry-proven wire-clamping technology, thick compression reinforcing rings and great selection of wire shapes.

Highest production loads and hard-to-screen raw materials. Accurate slot width without compromise for good shives removal efficiency and very long lifecycle.

More than 200 baskets delivered to BCTMP, TMP applications.

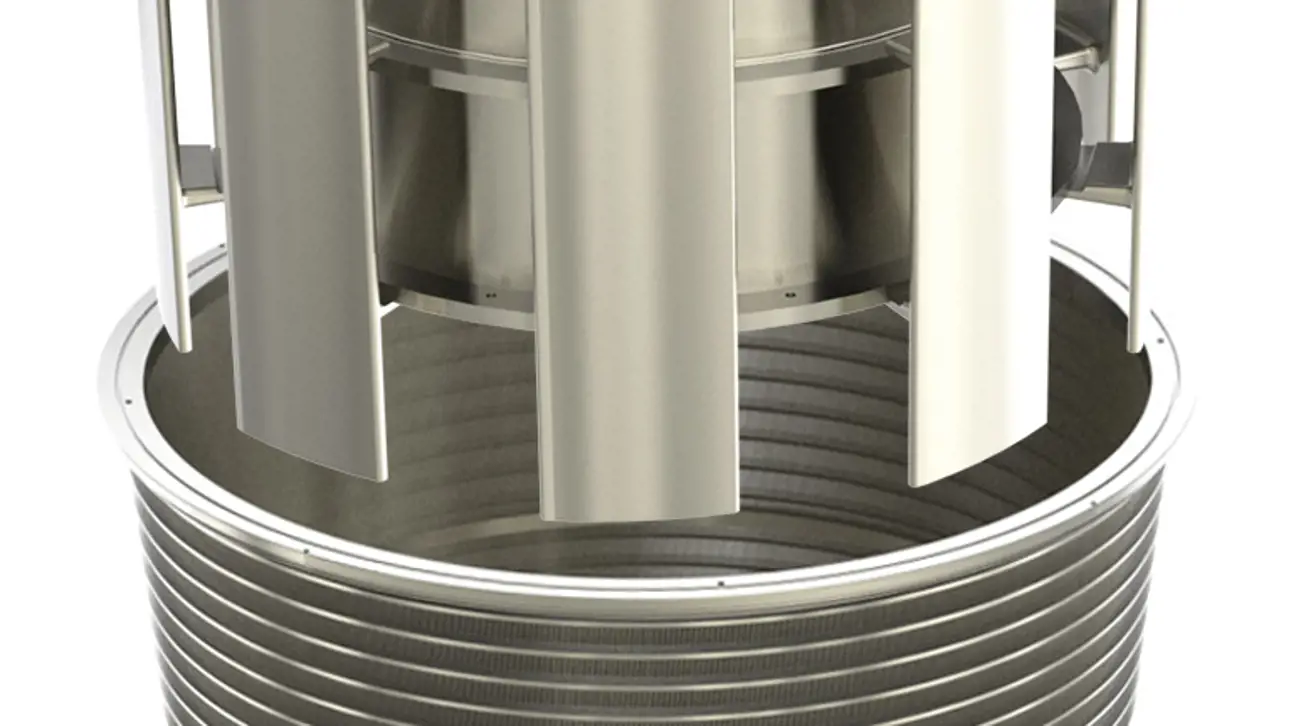

Low Energy Rotor

Ideal foil shapes for mechanical fiber low- and high-consistency screening. Gentle foil pulsation makes shives co-rotate more away from slots, keeping slots clean and ensuring good flow capacity.

Rotor’s open conical construction very tolerant of fluctuation of consistency and drop in pressure because of large co-rotating fiber suspension volume.

Do you have any questions?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact usScreen Basket VF - Low energy consumption

Valmet Screen Basket VF, is the only basket on the market that delivers energy savings by generating laminar flow into the pulp as it passes the screen basket before the headbox. The laminar design wedge wires provide higher capacity with lower energy consumption. The VF basket also ensures targeted pulp quality and high screening capacity in all operating consistencies, with excellent screening runnability.

Proactive screen basket recoating service

Our highly skilled product teams have developed a proactive recoating service to optimize screening performance. This innovative service ensures the screen basket profile is always maintained in top shape by replacing and recoating the baskets before their profile starts to wear. Knowing when to replace and recoat the baskets is the key to minimizing unplanned shutdowns, ensuring stable performance and saving costs.

Onsite inspections

During onsite inspections, Valmet’s service engineers inspect the baskets and measure their slot width, wear and general condition. The screen baskets are also inspected at the Valmet workshop when they arrive for recoating.

References and success stories

Excellent runnability at Norske Skog Bruck

Valmet’s innovative laminar design was installed at Norske Skog Bruck’s PM 4, with great results:

- Fewer breaks

- Better runnability

- Improved flow through the basket of the primary screen, noticeably improving overall screening performance

- Spinning was significantly reduced.

"The cooperation was very smooth, and we appreciate Valmet’s way of looking at things from our perspective”

- Enzo Zadra, Managing Director, Norske Skog Bruck

Nine days without breaks – Lessebo, Sweden

When they were running conventional screen baskets, our customer Lessebo mill in Sweden used to have three web breaks every day, colored spots in the end product and spinning problems. After installing one Valmet Screen Basket VF with a laminar design, they reached as many as nine days without web breaks, an end product with a good visual appearance and spin-free operation. The investment’s payback time was only a few days thanks to great savings in operating and energy costs.

Other references and articles