Improve capacity with optimized batch cooking

Valmet Batch Cooking Optimizer

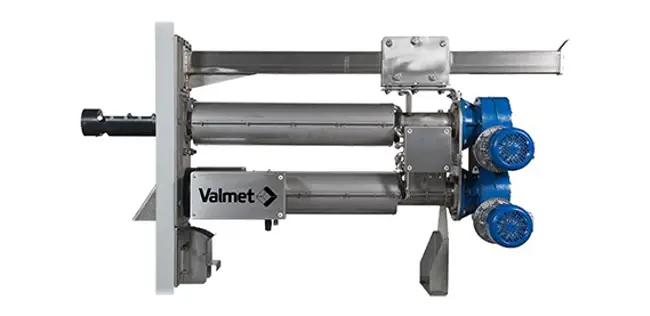

The Valmet Batch Cooking Optimizer is designed to manage pulp quality and production rates, including digester scheduling.

Advanced controls for high repeatability of batch cooking

Increased production with less variation in quality

Reduced energy and chemical consumption

The Valmet Batch Cooking Optimizer maximize production and delivers high cooking repeatability from batch to batch. Advanced sequence controls including automatic cooking cycle controls, related calculations, and cooking recipes help operators confidently optimize each batch cooking.

An optimized batch cooking plant produces consistent quality pulp in the correct amounts, at the right time, and with minimized raw material costs. The batch optimizer plays a decisive role in the control of raw materials and energy flows, as well as variables such as production rate, wood species, Kappa level, and disturbance management.

The production rate control determines the intervals between cooks, automatically accounting for possible limitations such as the number of digesters in service or steam consumption. With the Valmet Batch Cooking Optimizer, energy consumption can be considerably reduced through precise heating of the digesters and lowering cooking temperatures.