Journal inspection, dryer bearing fit and internal clearance

Mar 20, 2018

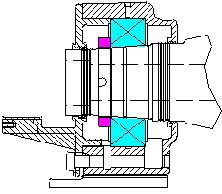

After a dryer front bearing has been removed, the bearing fit and new bearing to be installed internal clearance should be inspected. The following instructions outline the inspection procedures:

Journal inspection

- Clean excess oil from the journal and passages. Inspect the journal for damage such as nicks and burrs.

- Apply bluing to a sine bar, Set the bar on the journal and move it back and forth slightly while applying downward pressure. Verify that there is a minimum of 80% contact between the sine bar and the journal based on the amount of bluing on the journal.

- Repeat the sine bar check at 90º intervals around the journal.

Bearing inspection

|

NOTE: If the bearing is used, clean it to remove any material that could interfere with the internal clearance check. If the bearing is new, unwrap it and set it on a table so that it can be easily handled. Any slushing compound or rust preventive need not be removed from the bearing. |

- Verify that the bearing is at room temperature. If the bearing is extremely cold or hot, the clearance check will not be accurate. The bearing should be at room temperature during the clearance check.

- Check the bearing number to verify proper application.

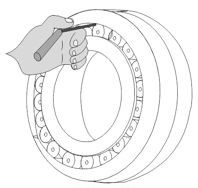

- Check the internal clearance of the bearing. Stand the bearing on its outer race, With one hand grasping the lower portion of the inner race, turn the inner race back and forth a few degrees. This will properly seat the rollers in the bearing.

- Insert the feeler blade between two rollers and the outer race. Slide the blade between the outer race and the roller nearest to the top of the bearing with a saw type motion. Do not roll the roller over the feeler gauge. Insert successively thicker feeler blades until the blade will not pass.

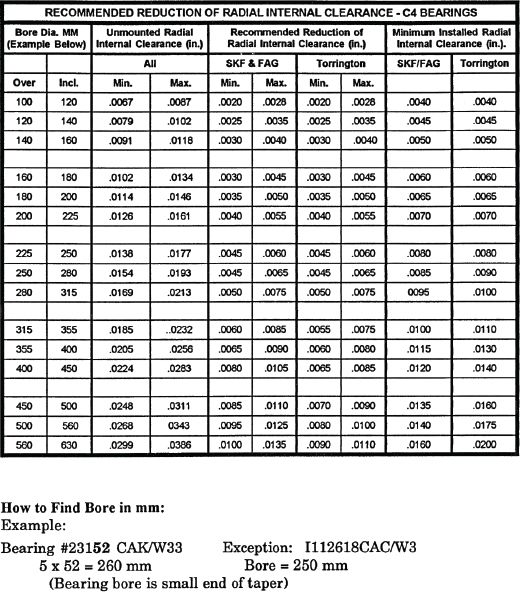

- Make note of the unmounted internal clearance. Check with the bearing chart to make sure it is within tolerance.

|

NOTE: If a sine bar is not available, the bearing fit can be checked with bluing and a new bearing. Apply a thin coat of bluing to the journal bearing surface. Slide a new bearing on the tapered journal until it stops. Remove the bearing and check the amount of bluing deposited on the inner race. The race must have a minimum of 80% surface contact with the journal. |

You may now proceed with the installation of the replacement bearing.

For more information on dryer maintenance, contact your Valmet representative.