Air guide maintenance guarantees trouble-free even operation

Feb 13, 2018

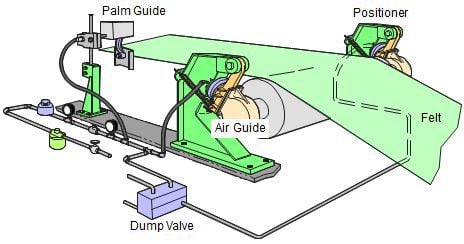

All machines that use a continuous belt, require a means of controlling the side-to-side movement of the belt. Typically this occurs by pivoting a roll, thereby straightening or "guiding" the path of the belt. Initially, belts were driven by a manual crank, but this quickly gave way to the air powered guide. In the air guide, a valve controls air flow based on a sensor that responds to the changing path of the belt. The air flow will increase or decrease of a cylinder or diaphragm and shift the guide roll, thus changing the path of the belt. The air guide is common on paper machines, where the continuous belt is the machine clothing. Proper care and maintenance of the air guide is essential to make sure that the guide works evenly and troublefree.

Guides are designed to keep the felt on and tracking properly.

Lubrication

Beloit vertical air guides have Oilite bushings, which require no lubrication. Straight-line guides require lubrication once a year. Other air guides have bearings, which require regular lubrication. On a weekly basis, apply a small amount of high-grade grease to each grease fitting. The control palm mechanism does not require lubrication.

Cleaning

Air guides must be kept clean. Vertical air guides must be hosed down daily to keep material from accumulating on the guide behind the roller.

General maintenance

Weekly, drain all accumulated moisture out of the air filter and out through the petcock located at the base of the diaphragm cover on the guide. If the opening of the orifice valve becomes clogged, it can usually be cleared by turning the plug 180°. The valve plunger may require occasional attention. If the palm fails to follow the fabric or felt, the tapered plunger may be fouled, sticky or rough. If it is sticky or fouled, dismantle and clean with solvent. If it is rough, use a fine compound to smooth out the contact area.

Spare parts

It is suggested to keep one spare diaphragm or airide on hand at all times for each guide. Most mills change all diaphragms at predetermined periods. An inspection program would be advisable with suggested time of 1 month maximum. On paper machines using a number of air guides, it is advantageous to keep one spare guide, one spare palm and an air control valve assembly for each type guide. Any unit on the machine may then be replaced quickly to permit a convenient maintenance check-up later.

Storage of diaphragms

Proper storage of spare rubber diaphragms is essential to prevent deterioration before usage. The ideal storage area is a cool, dry place where the temperature does not exceed 70 °F and temperature fluctuations are moderated. A dry atmosphere free from oil, grease, sunlight and excessive heat is recommended. Diaphragms should be stored in a flat, horizontal position to prevent distortion and wrinkles. They must not be folded, hung or stood on end, and other objects must not be laid upon them.

For more information on air guide maintenance and upgrades, contact your Valmet representative.