Safety, operation and maintenance of water jet tail cutter

Sep 8, 2015

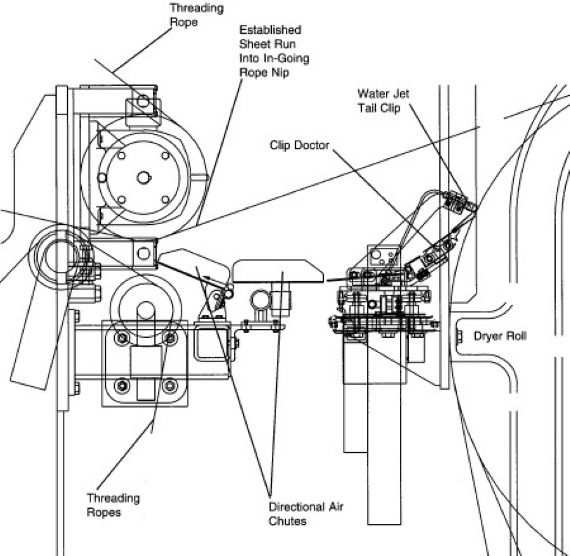

The water jet tail clip is made from fabricated steel and is equipped with a special high pressure nozzle used for cutting the tail. A doctor blade and holder are included with the assembly. An air pipe and a deflector pan are mounted to the tail clip. The water jet tail clip is retracted from the roll face for storage.

Operation

The water jet tail clip is normally in the STORE position off the roll face. For operation, the tail clip is moved into the READY position via the supplied controls. To initiate threading, the doctor blade loads into the roll face, the air pipe turns on and the high pressure water jet turns on. The clip automatically traverses inboard, cutting the tail and doctoring it from the roll. The air pipe blows the tail into the threading conveyors (air chutes or rope nip). Once the tail is threaded, the clip retracts to the READY position and the water jet tail clip and the air pipe are turned off. The doctor blade also unloads. The tail clip is then returned to the STORE position.

Water jet tail clip cutting the tail on the dryer

Safety

Refer to the operating manual that accompanied your water jet tail clip for comprehensive safety guidelines. The following are a few specific precautions, but by no means a complete list.

- All personnel working with this equipment must treat it as they would treat any high-speed cutting tool. Although the water jet may appear harmless, it is a high-energy cutting item capable of cutting a multitude of non-metallic materials, such as composites, plastics and wood products.

- High pressure water will remain in the lines for a prolonged period of time unless the pump is equipped with an automatic bleed down system.

- Make sure that the system pressure is bled down before servicing any part of the system.

- Some of the fittings, connections or parts are equipped with weep holes. Do not touch these holes with your bare hands or try to stop dripping water by clogging the holes.

- Do not subject any part of your body to the water jet stream. It is indeed a "knife."

Water Pump

The original Beloit Water Jet Tail Clip was supplied with a Cougar Model S-10 pump. This is a direct-drive plunger pump capable of output pressures to 40,000 psi and flow rates of 0.42 gpm. The pump is powered by a 10 hp electric motor. The Cougar S-10 is designed for continuous-duty applications.

Take the following precautions when performing maintenance on the Cougar or other water pump:

- To avoid damage, do not lubricate the motor excessively or too frequently.

- Protect all machined and lapped mating surfaces against nicks, scratches and burrs.

- Carefully work out any damage to a seal wiping surface.

- Carefully clean and blow out all parts being reassembled. Do not use paper towels. Do not create air-borne dust.

- Do not use a substitute for the fluids, sealants and lubricants recommended by the pump manufacturer.

- Clean off grease fittings before connecting grease gun to avoid dirt filled grease being injected into the bearings.

- New bearings are frequently packed with only a light shipping grease. Be sure they are properly lubricated before operation.

The daily inspection includes before and after start-up checks that will help prevent failure of the equipment. Before start-up take the following actions:

- Inspect the pump, high-pressure tubing, connections and valves for signs of leakage. Correct any problems before starting the pump.

- Check the oil level dipstick.

- Check the main electrical disconnect for "Out of Service" tags and check all around the equipment for indications of maintenance work in progress.

Then listen for unusual sounds as the pump is started and water pressure increases.

For more information on the operation and maintenance of water jet tail cutting systems, contact your Valmet representative.