Polarized forming fabrics for great water removal, case studies

Mar 6, 2018

Valmet introduced a generation of forming fabrics with a polarized structure in 2016. Customer experiences have shown that these polarized forming fabrics have the potential to revolutionize water removal in the papermaking process.

Sheet support binding (SSB) forming fabrics entered the paper and board industry in the mid-90s. Since then, these fabrics have been made thinner and finer to achieve higher retention, excellent paper and board quality, and to improve the runnability of the machines.

However, thinner forming fabrics started to face durability problems, and product development needed to find a new solution to meet customers’ expectations.

"In 2016, we introduced a new polarized structure in the forming fabrics. Based on the experiences we have so far, we most likely created something that will revolutionize the water drainage process in the wire section," says Pekka Kortelainen, Product Technology Manager for Forming Fabrics at Valmet.

Polarized structure improves machine runnability

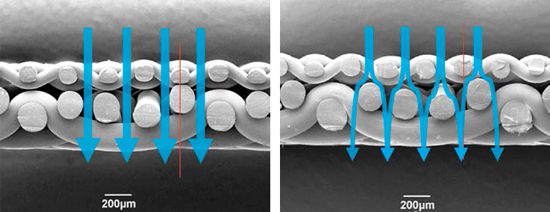

Traditionally, all SSB fabrics have had direct drainage channels. In the polarized structure, the machine direction yarns on both the paper side and the roll side are shifted to form an off-stacked structure. This special structure removes the direct drainage channels traditionally used in forming fabrics.

(Left) Standard SSB fabric has straight-through drainage channels. (Right) With polarized fabric, the machine direction yarns eliminate the straight-through channels.

"The unique polarized structure allows controlled initial drainage in the paper-making process. That improves retention and helps keep the machine clean. Good runnability and cleanliness reduce breaks, which remarkably increases production capacity and leads to cost-savings through reduced use of chemicals," explains Kortelainen.

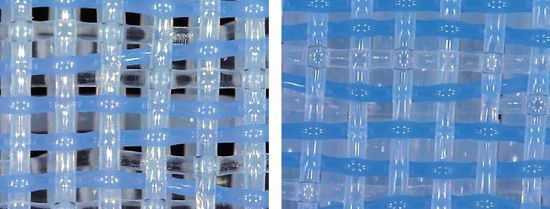

(Left) Standard SSB. (Right) Polarized fabric warp provides true diffuse drainage.

Demand for polarized fabrics growing

To date, Valmet has sold over 300 polarized forming fabrics. "I am pleased to say that over 90% of the customers who have tested the new fabric type have seen its benefits and continued to run it on their machines. The customer feedback has been extremely positive. We are able to utilize the polarized structure in all our SSB forming fabric types, which naturally makes it suitable for all machine types," explains Kortelainen.

Valmet Forming Fabric GM, a polarized fabric, has become popular with papermakers. According to one operations manager, "From the first set, we saw the advantages of the polarized structures: We were able to significantly improve formation as we wanted, but the cleanliness and runnability were also good, and the dry content remained excellent. Since that first trial, those polarized fabrics have become our standard Valmet design fabrics."

In addition, here are a few other in-mill experiences:

Case 1: Improved cleanliness

A customer is running newsprint and has been using standard SSB fabrics for years. Their normal way to run was to have a cleaning stop once a week. When they tested the polarized Valmet Forming Fabric GM, they noticed that the machine ran cleaner and no extra stops were needed. Wet end breaks fell by 50%, and the machine set a monthly production record. Based on the figures after a two month test period, the production capacity would have increased by 6,500 tonnes a year.

Case 2: Higher retention

A customer is producing fine paper and has been using Valmet’s standard fabrics for years. Retention has been around 82%. The customer conducted a trial with an other supplier’s super-fine fabric and was able to increase retention to 86%. After Valmet’s proposal, the customer was willing to test Valmet’s new polarized fabrics in the bottom position. The results were very good, as retention increased to 91% and the machine ran cleanly. As the trial was successful, the customer ordered a set of polarized fabrics for both

positions.

Case 3: Lower-roughness two-sidedness

A customer’s machine has moved to more calendered, improved news grades. There has been demand for lower-roughness two-sidedness, as the top side PPS roughness has been 20–25% higher than the bottom. After changing to Valmet Forming Fabric GM, the difference decreased to 15%, but a trial run was still performed with a polarized version of the same fabric type. The experiences were very good, as the roughness difference decreased to 8%, combined with very good runnability. As a result, the customer ordered a similar set.

For more information or to try Valmet's polarized fabrics on your machine, contact your Valmet representative.