Passaic Valley: Accurate sludge solids measurement means big savings

Nov 23, 2015

A USA waste treatment plant sees a $1.2 million/yr reduction in chemical and energy costs with the implementation of Valmet TS online measurements and automatic centrifuge controls.

Hundreds of Valmet TS inline total solids meters have been successfully installed in waste water treatment plants in North America, providing an excellent return on investment based on savings of polymer addition rates, energy costs and sludge disposal and shipping costs. Typical savings can be in the tens of thousands of dollars per year, but quite regularly a “star performer” stands out where the savings and the ROI are much higher. Such a case has been reported at the Passaic Valley Sewerage Commission (PVSC) in Newark, NJ, USA. The reliable readings of the Valmet TS meters that measure feed and discharge solids to four centrifuge thickeners are used to precisely control the thickening operation, responding to changes in input solids and stabilizing the outlet. These measurements and controls reduced the thickened sludge volume by 9%, resulting in savings of $1.2 million in energy and chemical usage.

The results of the solids meters’ installation and control was reported in the October 2014 issue of Water Environment & Technology (WE&T) Magazine in an article entitled “Once I was blind, but now I can see”, whose authors included PVSC staff. The authors make the excellent point that, “Operating a sludge or biosolids process without knowing the percent solids in the influent and effluent is like driving a car blindfolded. This data is critical for sludge, as the associated costs for treatment are as much as 50% of the entire cost of operating a water resource and recovery operation."

|

The need to reduce costs led PSVC to look at new, more time effective ways to measure total solids online. Tests by operators every four hours were time consuming and not timely enough for precise, real-time thickening control. Changes in centrifuge feed solids would sometimes result in over-thickening and clogging. Existing inline optical instruments were troublesome due to air bubbles in the flow, different particles sizes and solids color differences. They were never used for accurate solids measurement and automatic controls. PVSC tested the Valmet TS which is based on microwave time of flight measurement of total solids with an internal correction measurement of sludge conductivity. PVSC reasoned that, with a reliable continuous measurement, the sludge could be thickened without operator involvement to an optimum point where operating costs could be reduced.

Variable solids means higher energy

The PVSC facility processes 14.5 m3 (330 mgd) of sewage from a population of 1.3 million in 48 towns and also processes 3.4 ML/d (900,000 gpd) of out-of-district liquid waste delivered by trucks and barges. The sludge mix constantly changes in amount and source. The various sludges, mixing ratios and seasonal fluctuations result in centrifuge feed concentrations between 1.8 % and 4.8%.

Passaic Valley utilizes wet-air oxidation treatment for sludge conditioning and volatile solids reduction prior to dewatering treatment. Each wet-air oxidation treatment unit uses a fixed amount of energy to heat each gallon of sludge independently of the feed sludge solids. A thicker sludge therefore decreases the total flow and the number of treatment units, minimizing energy consumption. The operating goal is to be as close to but not exceeding 6.0%, above which clogging and mechanical damage can occur. Without reliable online measurement the operators run the process manually below this optimum thickness, resulting in higher than necessary energy costs.

Effective automation, $1.2million in savings

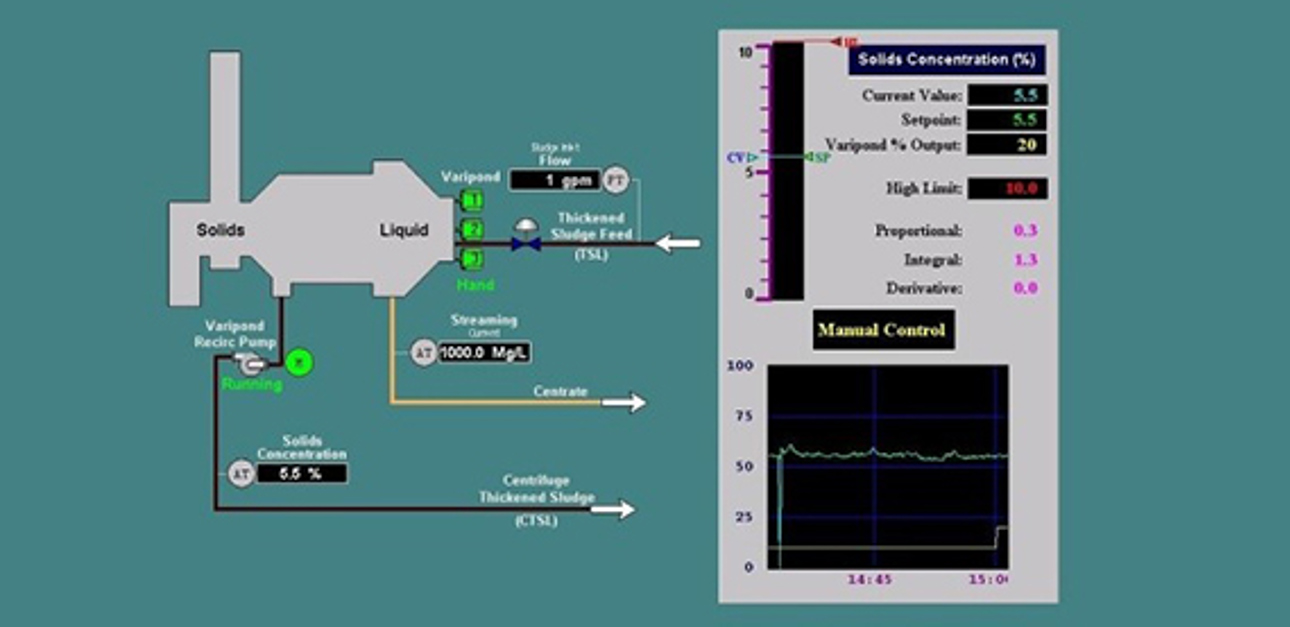

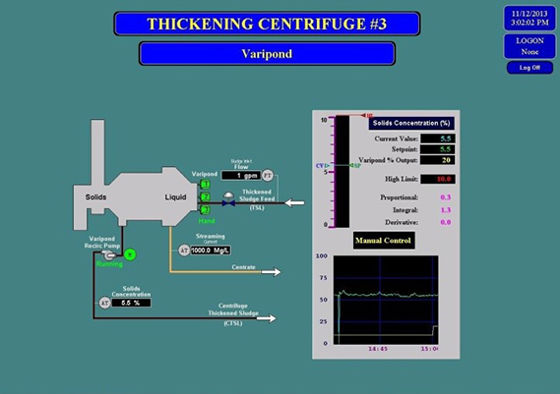

The designed-in automatic solids thickness control for the centrifuges involved varying pond depth as shown in Figure 1. Since that was never realized with the existing instruments the Valmet TS was tested. The instrument readings correlated almost perfectly to the laboratory tests with a correlation R2 of 0.97. There was an initial problem with the centrifuge discharge measurement until Valmet pointed out that the sludge line pressure should be increased to 1.5 bar to collapse entrained air bubbles created in the centrifuge. After that process change the new Valmet TS proved its worth according to the article authors. The correlation R2 was an excellent 0.98. Problem solved!

Figure 1: Automatic control scheme for centrifuge thickening

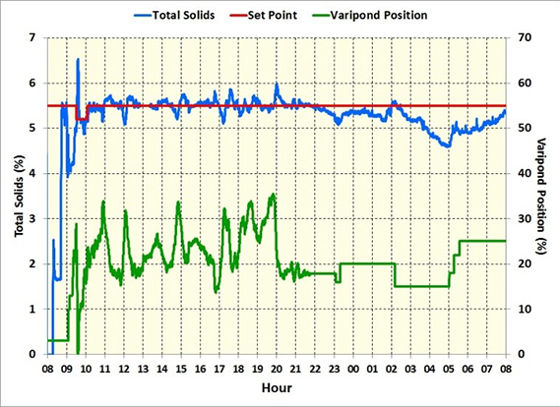

Next, a full-scale control test was made on one centrifuge with the collaboration of PVSC staff and the centrifuge manufacturer. The successful trial shown in Figure 2 shows how automatic control stabilizes the discharge solids content. After that, all four centrifuges were equipped with Valmet TS, measuring the feed and discharge. PVSC points out that the instruments have no moving parts, so the maintenance is minimal.

Figure 2, Automatic thickening control (left side) by pond depth improves stability of centrifuge outlet solids

The end result is that automatic centrifuge adjustments based on changing feed solids has reduced the sludge volume by an average of 9%. The reduction in flow to the wet-air oxidation treatment will save PVSC $1.2 million in both energy and chemical costs.