The 1 Mile Rule analogy of MD length profiles and bagginess

Nov 8, 2016

The "1 Mile Rule" is an interesting analogy regarding how machine direction length profiles affect baggy lanes. Baggy lanes occur when machine direction tension is lower compared to the web around them. In fact, baggy lanes are caused by differences in web length. The greater the relative length differences are, the more severe the baggy lane will be.

Baggy lanes create many issues on the machine or on downstream equipment. Baggy lanes don’t do well when run through any type of nip (size press, calender, reel) and can cause wrinkles anywhere on the machine.

Basically the 1 Mile Rule goes something like this. If you take a 1 mile long strip of paper (5280ft), put it on the ground and stretch it 1 foot - you now have a 5,281ft web. Now, if you were to take the two ends of this paper strip and push them back together such that the ends return to their original 5280 feet length, the paper will buckle upwards. Just how high the paper buckles will astound you – it rises over 50 feet in the center. Do the math if you want to verify this.

The bottom line is this – very small differences in machine direction length will create baggy lanes and the problems associated with them. Yes, the basis weight, moisture, and caliper profiles may correlate with baggy lanes too, but it’s the length differences that are actually creating the baggy lanes. What causes some parts of the web to be longer is the ultimate question – forming, pressing, drying, and/or calendering.

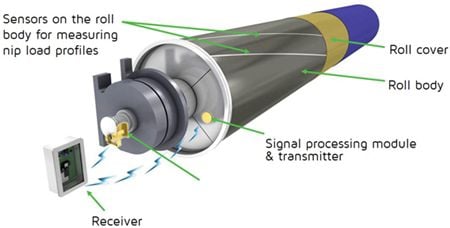

Valmet iRoll system components toolset for the control of paper and nips.

Valmet has a technology - called iRoll - for measuring these baggy lane tension profiles. A cross directional sensor which measures tension profiles in the sheet is attached to a roller or reel drum. Once a baseline is established, process changes in the press section, dryers, or calenders are made and their corresponding results are seen immediately. There is no waiting for the turnup in order to perform reel structure testing; the necessary measurements are performed online in realtime. The Valmet iRoll system, either permanently installed under a roll cover or used on a temporary basis as Valmet iRoll Portable, will show quantitatively the response to each process change. After determining which process variables affect baggy lanes the most, trials may be conducted to optimize the sheet structure.

For more information on reeling/winding, baggy lanes and iRoll contact your Valmet representative.