Maximum equipment performance through modular maintenance solutions

Apr 4, 2016

Valmet’s modular maintenance solutions offer pulp and papermakers clearer choices for the maintenance of all rolls and equipment for fiber production. This helps the customer to make wise maintenance choices, for efficiency and maximum performance.

Valmet serves over 2,000 mills and plants worldwide from over 100 service locations. We want to serve our pulp and paper customers efficiently and transparently which has led to modularizing our maintenance services for rolls and equipment for fiber production.

Reaching improved performance together

Pulp and paper makers are constantly aiming at improving productivity, and for that reason the focus of the modular services is on maximizing performance. The customer can be actively involved in decision making and the choices have been made easy and clear.

Valmet can provide specific-for-you expert recommendations of optimal service solutions. Arne Wessbladh, Director of Workshop Services explains that Valmet experts will “work with the customer to find out what real issues they are facing and help find applicable solutions and answers to these specific needs.” In this way, the customer can make an informed choice of what options suit their immediate and future needs the best. Additionally, upgrades and modernizations can also be suggested and where there can be room for improvements in availability or performance.

Valmets technology and global expertise can complement the customers in their operations. The aim is that the customer gets the best out of Valmet as the partner. The customers do not have to worry about paying for unnecessary activities.

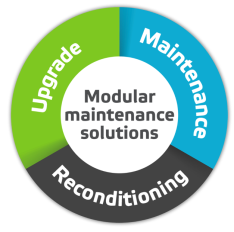

Modular maintenance solutions

|

The modular maintenance of rolls and equipment for fiber production is divided into three modules. Maintenance services: The basic scope of the work is to ensure components are in acceptable operational condition, saving on long-term maintenance costs. Reconditioning services: Thorough inspections of present component condition, an inspection report and proposals for possible additional work and part replacements needed to bring component to “as new” condition. Upgrade services: Offering upgrades on existing components with modern features, based on customer needs, to enhance performance and productivity. |

|

The modular approach means that the customer knows what to expect from each service solution. This also ensures purposeful service actions and best possible use of assets. The customer can ensure the best availability and safety and save on maintenance costs.

Moreover, through Reconditioning services and value-adding repairs, benefits can be seen through extended running time, better energy efficiency and runnability, and improved end product quality.

Modular maintenance solutions are especially targeted for equipment like digester feeders, TwinRolls, refiners as well as critical process rolls such as deflection-compensated rolls and suction rolls.

Uniform quality all over the globe

A globally uniform high quality is the core of Valmet’s service operations. This is achieved through agreed standards and practices all around the world.

Timo Karonen, Global Technology Manager for Roll Maintenance Services, explains how the customers will benefit from modular service solutions: “The modularity clarifies service-related communication between the customer and Valmet and minimizes the chances of any misunderstandings. It also streamlines maintenance lead time, makes our services more flexible and lets us meet each customer’s service needs in the optimum way.”

makes our services more flexible and lets us meet each customer’s service needs in the optimum way.