Technologies for coated board production

Sales of consumer goods increase every year, and need for packaging and transportation along with it. So have you ever stopped to think how important light-weighting is today? Especially in materials like coated board.

Packaging producers get lighter board for their products

Transporting lighter products decreases the environmental impact

Each product creates less waste when recycled

Less energy is needed at every stage

Lightweight but strong

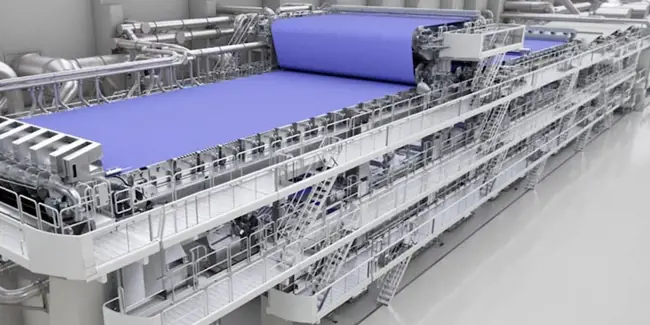

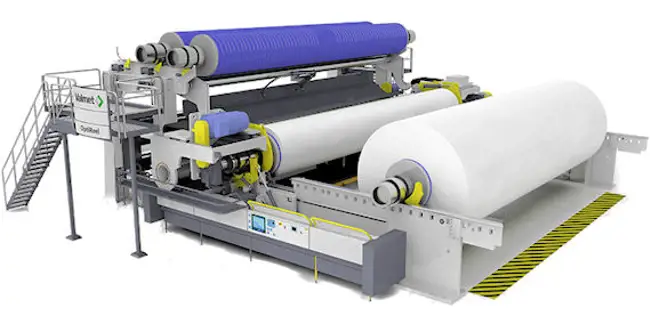

For our customers, the coated board producers all over the world, creating lighter end products is nowadays the lifeblood. The benefits of lightweighting are felt at each stage of the value chain as lighter board means savings in raw materials, energy consumption, and transportation costs. Lightweighting means that at least the same end-product quality can be produced with less raw materials. In practice, a 10% saving on raw material means that 10 out of 100 trees are left growing in the forest and 10% less trucks and energy are needed. Or, an average mill can produce 700 million milk cartons more per year from the same amount of raw materials.

As coated board producers are committed to creating innovative and sustainable packaging solutions that allow brands to connect with consumers all around the world, we as Valmet are committed to helping them. With our solutions, they get lighter board without compromising on functional or visual properties so they can create packaging solutions that truly drive brand loyalty. At the same time the amount of energy and raw materials used can be substantially reduced. Watch the video to hear more about our thoughts on lightweighting.

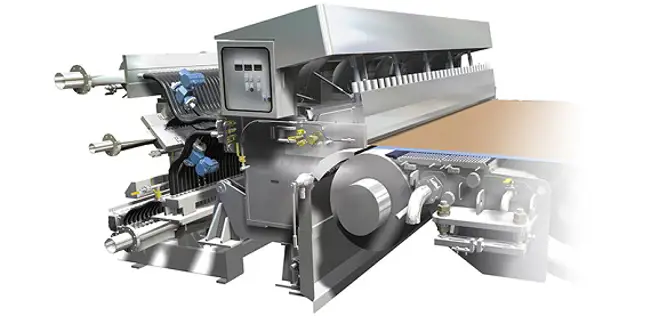

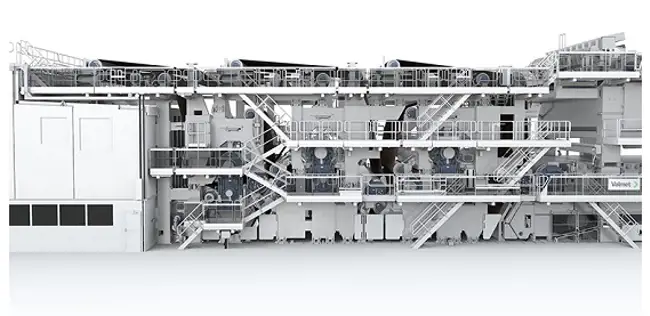

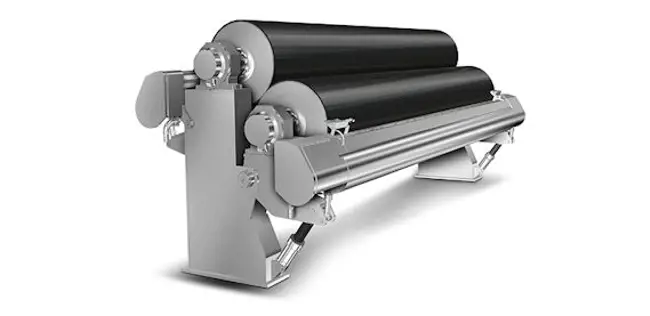

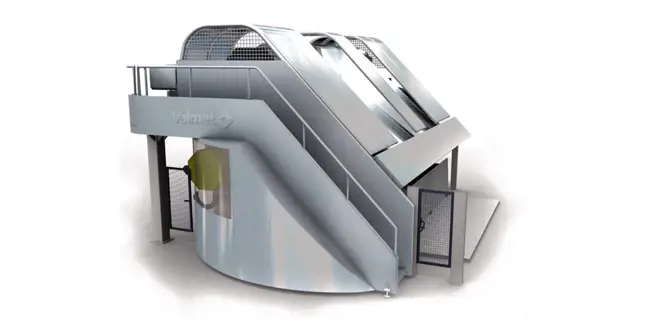

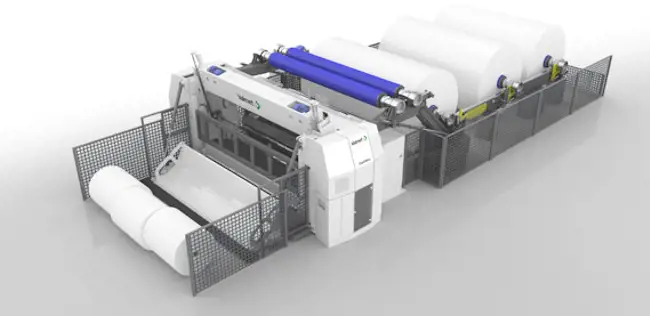

Our offering for board producers includes everything you need when producing coated board cost-efficiently. We cover the entire life cycle of processes: new installations, rebuilds and services as well as automation solutions to guarantee that your paper machine runs smoothly, energy-efficiently and uses raw materials economically while being safe to use.

Valmet Technology Centers offer excellent piloting services to find the optimal concept and technological solution for your needs.

Explore our latest board and paper press releases

- Jan 11, 2024Valmet to supply key technology for Shandong Jin Tian He Paper’s board machine in China

- Oct 25, 2023Valmet has received a major order of multiple technologies from Liansheng Pulp & Paper in China

- Oct 4, 2023Valmet introduces a new rotating consistency measurement for pulp and paper producers

- Sep 26, 2023Valmet to supply a fine paper making line to Yueyang Forest Paper in China

- Aug 31, 2023Valmet to supply key pulp and paper technologies to Naini Papers in India

- Jul 19, 2023Valmet to supply a high-capacity winder to Gascogne Papier in France

- Jul 4, 2023Valmet to supply an OptiFlo headbox and Valmet Conical Refiners to Shree Ajit Pulp and Paper Limited in India

- May 8, 2023Valmet to rebuild ITC’s board machine in India

- Apr 25, 2023Valmet to deliver key technologies for Henan Longyuan Paper’s testliner line in China

- Mar 27, 2023Valmet to supply a new container board making line to DS Smith in Italy