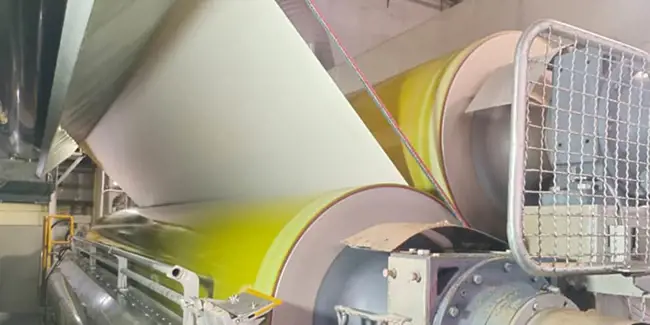

Workshop and roll services for board and paper making

Keeping your production rolling with optimal performance

How does your business sound like? Hopefully, there are no roll related vibrations, annoying production breaks or disturbing shutdowns. Valmet Workshop and Roll Services offer a winning combination of the latest roll technology and maintenance expertise. We help you eliminate unplanned shutdowns, increase the running times of rolls, improve the end product quality and lower the roll maintenance costs in long-term.

Increased roll running times

Improve end product quality

Avoid unplanned shutdowns

Minimize roll maintenance costs

Top performing production line for board and paper making

Every board and paper maker expects a top performing mill with optimal runnability and an output that meets the market quality and demand. Valmet Roll Services has got a vast amount of expertise to move your mill’s performance forward. The wide selection of services extends from roll maintenance to upgrading and new roll technology as well as roll covers and intelligent roll solutions.

Our unique offering for different grades

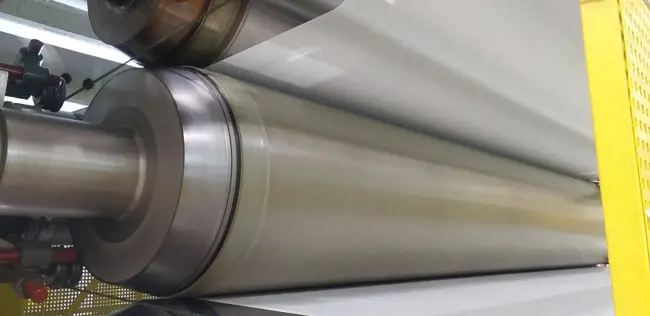

Optimal paper quality and production efficiency

Rolls have an essential impact on paper quality and production efficiency. We can help you increase your roll performance with a full range of roll products from the state-of-the art new roll technology to roll upgrades, and to the best-fit-to-purpose roll covers.

Read more

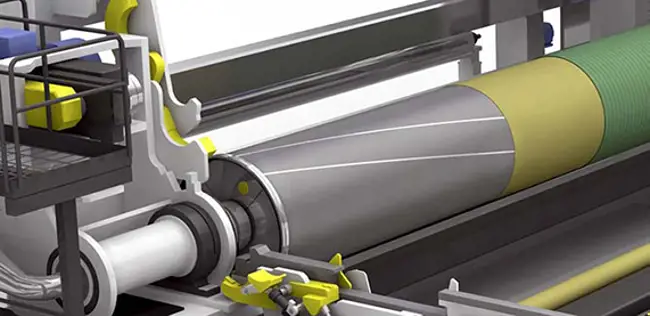

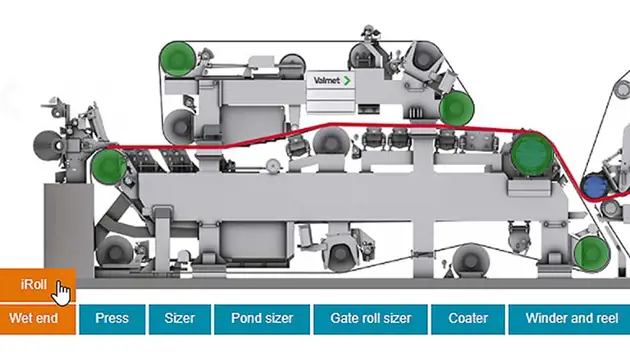

Explore our roll cover products from interactive demo.

By exploring this roll cover application tool you can easily see different cover options for every board and paper making process.

Start exploring

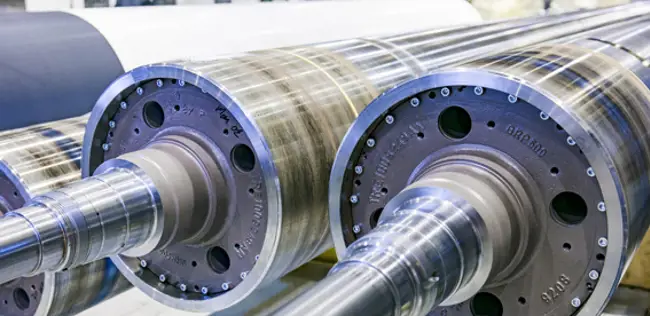

From time to condition-based roll maintenance

The condition-based maintenance services enable planning maintenance actions based on the actual condition of your equipment. Customers can see a significant reduction in maintenance costs as root causes of faults can been identified and maintenance of rolls will be optimized leading to extended roll lifetimes and optimized maintenance intervals. Our Modular Maintenance Services consist of maintenance, reconditioning and upgrade services which allow you to build just the right combination of services for your mill. Read more about Intelligent Roll Solutions and Valmet DNA Machine Monitoring.

Read More

Roll Service Agreement - systematic approach to improve performance

The goal of roll service agreement is to ensure that customers can meet and exceed the requirements set for their operations. Valmet helps board and paper makers to maintain high levels of equipment operations, improve efficiency, and give all-round cost-control of their roll maintenance spend. With the help of roll services and upgrades, roll data management, intelligent roll solutions, continuous improvement, condition monitoring, industrial internet applications as well as audits and shutdown support, the performance of rolls can be raised to a completely new level.

Read MoreClose to you through roll service centers around the world

Our global network of roll service centers is available in over 25 locations around the world. In addition to that, there are Valmet's process industry professionals in over 120 locations worldwide and Valmet network of experts available with quick response time remotely. To reap the best benefits from these experts, you can get them as a part of your team through a roll service agreement.

Read MoreWant to talk to our roll service experts?

Answer a few questions and our roll experts will contact you shortly.

Contact usReferences and articles

Keep learning about our roll services