OptiSizer Spray

Accurate, fast and contactless size application

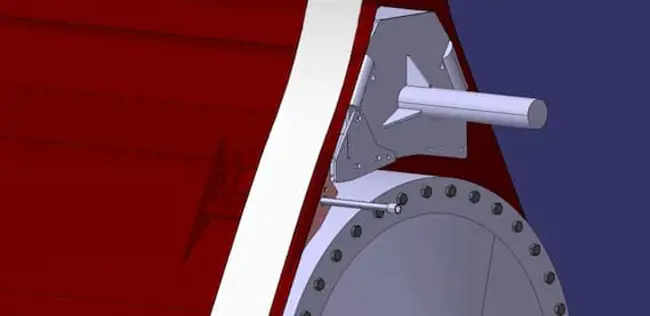

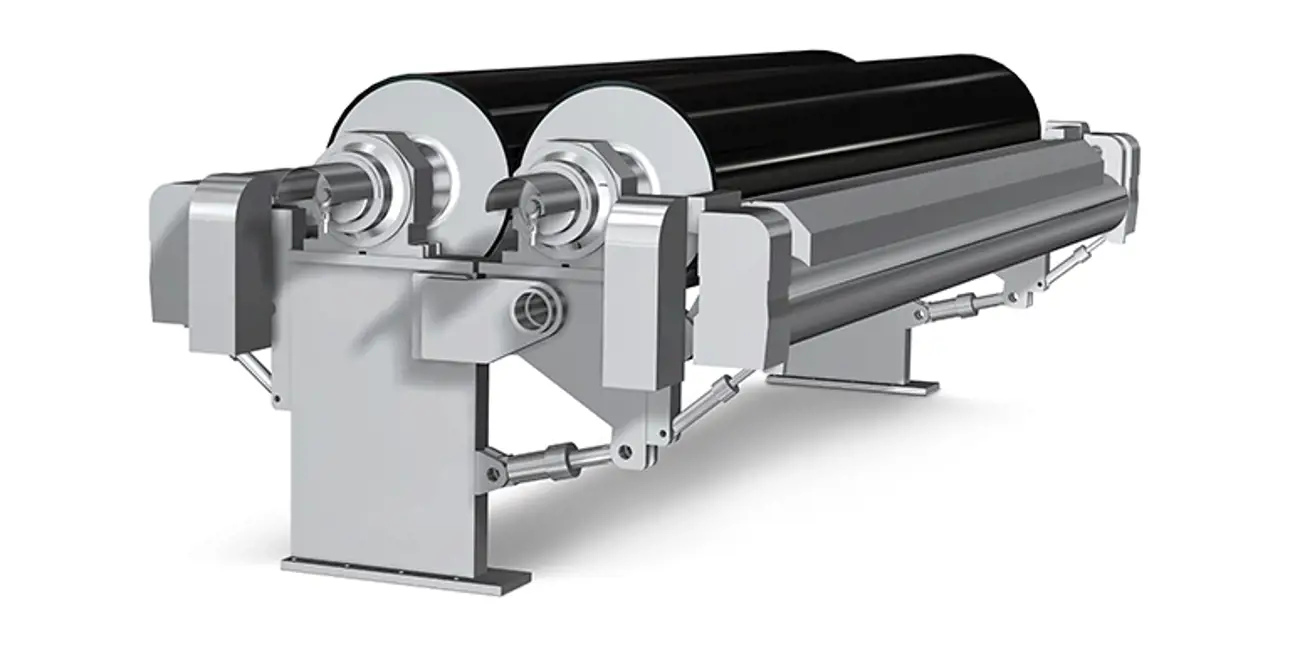

Surface sizing with spray application is a unique size application method. The size is sprayed on the nip rolls through a row of spraying nozzles. The rolls transfer the size to the web in the nip. You can control the amount of size accurately and fast, and there are no consumables due to contactless application, which leads into decreased downtime.

Optimized strength properties

Reduced drying need

High operational efficiency

Low life cycle costs

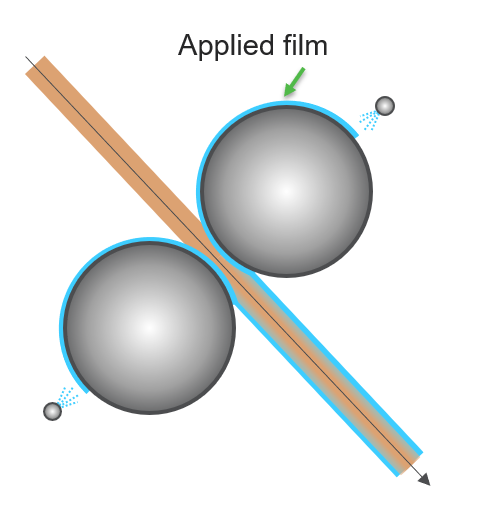

Principle of spray sizing

Spray application enables the size amount to be controlled accurately and fast by adjusting feeding pressure in the nozzles. The method also responds fast to changes in solid content due to low volume system. The application is contactless and there are no consumables. This is especially beneficial for liner and fluting producers who use old corrugated cardboard (OCC) as raw material since recirculated starch is never in contact with recycled fiber and there is no starch contamination.

Principle of spray sizing

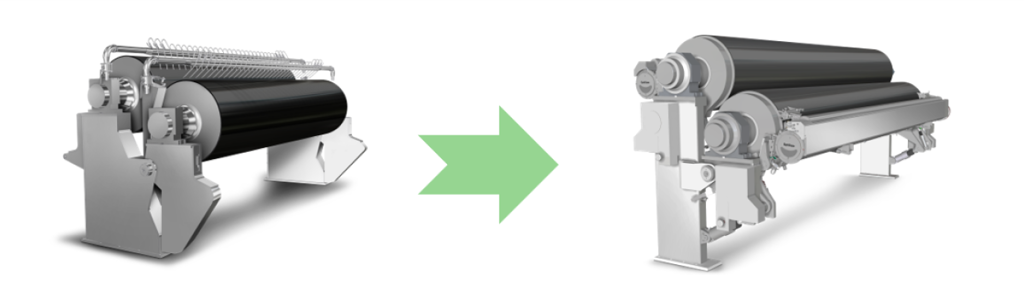

Pond vs. spray application

When you compare spray application to the traditional pond size press, the most important benefits are energy savings and improved runnability.

Energy-efficient operation

Solids content in spray application are very high compared to pond application method. There is a huge potential for energy – and money – savings due to reduced drying need. This means also that there is no need for a long after-dryer section, which leads into that more capacity can be directed to pre-dryer section.

As said earlier, spray application is a contactless form of size application. There is no size recirculation, so the size of the supply system can be smaller and more energy-efficient.

Improved runnability and higher dry content

Spray application method does not limit machine speed nor dry content of size. The method allows higher incoming web moisture levels because of lower sheet wetting and uniform CD profiles. Besides, there are less web breaks due to higher sheet dryness.

1. Wet paper = poor runnability

The basic idea with pond is to form flooded nip to make the size penetrate well into the paper. This makes paper web wet, and the wetted paper is prone to break easily, and machine runnability is decreased. To avoid this, the web is over-dried before the pond sizer to lower the sheet moisture.

2. Unstable pond = splashing markings in the paper

The ponds formed in the nip of the rolls need to be stable for a good result. If you want to increase the size pick-up, you need a higher dry content, thus viscosity of the wet size is increased. Again, the shortest way to increase production is to operate the machine at higher speeds. Both viscosity and speed increase turbulence in the pond, which causes splashing. This is why dry content, or viscosity, and machine speed must be kept low with pond.

These limitations are not applicable with spray application method; you can operate a fast sizer with size of high dry content and with a great runnability.

Film vs. spray application

When you compare spray application to film size press, the most important benefits are lower consumable cost and less down-time.

Lower consumable cost and less down-time

As the film of size is sprayed on the nip rolls, the application is contactless and the number of consumables minimal. The down-time is reduced significantly compared to film applications since there are no rods nor sealing blades to be changed. There is less need for roll grinding, because of the absence of the rod, which causes wearing of the roll surfaces. This is especially applicable with OCC, since film application and unclean starch lead into a short rod life time, higher wearing rate of the rolls or can limit starch dry content.

Accurate and exactly repeatable starch application

When size is applied with spray nozzles, starch application is not impacted by wearing of roll covers or metering rods. The size amount is accurately controlled by adjusting feeding pressure. It can response fast to changes in solid content due to low volume supply system.

We invite you to carry out your size application trials to Järvenpää, Finland at Paper Technology Center on the world's fastest and most modern pilot sizing and coating machine.

Interested in pilot trials?

Get in touch with our pilot trial experts to discuss how you could benefit from our pilot trial services.

Contact our pilot trial expertsHow to plan a successful rebuild?

Rebuilding a paper or board machine can improve the competitiveness of your business and your processes. Download our e-book to learn more.

Download e-bookPlanning a grade conversion?

The world is changing fast; the consumption of papers is decreasing and boards increasing. Update your paper machine with Valmet to produce more profitable products.

Discover moreLearn more about the services and automation solutions for sizing

Explore our latest board and paper press releases

- Jan 11, 2024Valmet to supply key technology for Shandong Jin Tian He Paper’s board machine in China

- Oct 25, 2023Valmet has received a major order of multiple technologies from Liansheng Pulp & Paper in China

- Oct 4, 2023Valmet introduces a new rotating consistency measurement for pulp and paper producers

- Sep 26, 2023Valmet to supply a fine paper making line to Yueyang Forest Paper in China

- Aug 31, 2023Valmet to supply key pulp and paper technologies to Naini Papers in India

- Jul 19, 2023Valmet to supply a high-capacity winder to Gascogne Papier in France

- Jul 4, 2023Valmet to supply an OptiFlo headbox and Valmet Conical Refiners to Shree Ajit Pulp and Paper Limited in India

- May 8, 2023Valmet to rebuild ITC’s board machine in India

- Apr 25, 2023Valmet to deliver key technologies for Henan Longyuan Paper’s testliner line in China

- Mar 27, 2023Valmet to supply a new container board making line to DS Smith in Italy