Quality improvements

Quality issues are high on the agenda of every paper and board mill, as optimal quality needs to be produced at the lowest possible cost. Valmet offers a wide scope of solutions and services for better end-product quality, from stock preparation to finishing. Stabilizing running processes in all phases of the process leads to cost-effective quality improvements that do not require major investments. We and our customers share the same targets: optimal quality at the lowest possible cost, consistently in all shifts.

Finding the root causes of poor quality

Valmet’s experts perform paper structure analyses that offer insight into disturbances in quality issues. Fiber orientation, formation, curl, bulk, smoothness, gloss and other quality factors are evaluated in laboratory conditions, including benchmarking and recommendations.

Better quality starts with stock preparation

Quality improvements in stock preparation do not just result in better stock quality – they also lead to energy savings and improved production efficiency. All stock can be treated more evenly with Valmet’s refining concepts, such as OptiFiner Pro. This high-capacity refiner provides the same or improved strength properties with lower costs. The enhanced bonding ability of the fibers improves paper machine runnability, resulting in better printability, fewer web breaks, and a uniform refining result.

Lost quality levels can be reinstated and profiles restored in a cost-effective way with Valmet’s headbox maintenance. Our headbox services provide a stable basis weight and even profiles throughout the production line, also improving end-product quality.

Do you want to discuss about quality improvements?

Answer a few questions and our paper & board experts will contact you soon after.

Contact our expertsImproved formation for better quality

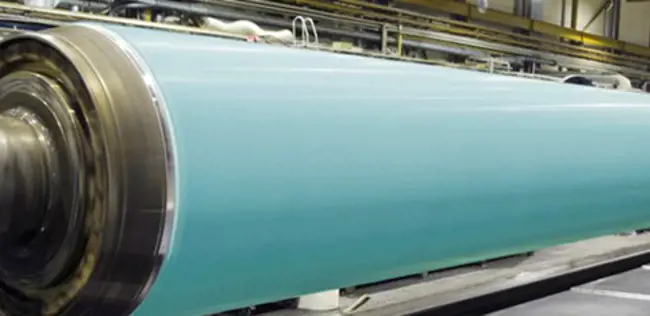

In the forming section, paper and board quality can be effected through furnish optimization and more uniform profiles, as well as improved strength and formation properties. If the target quality can be produced using cheaper furnish, the results are visible in the bottom line.

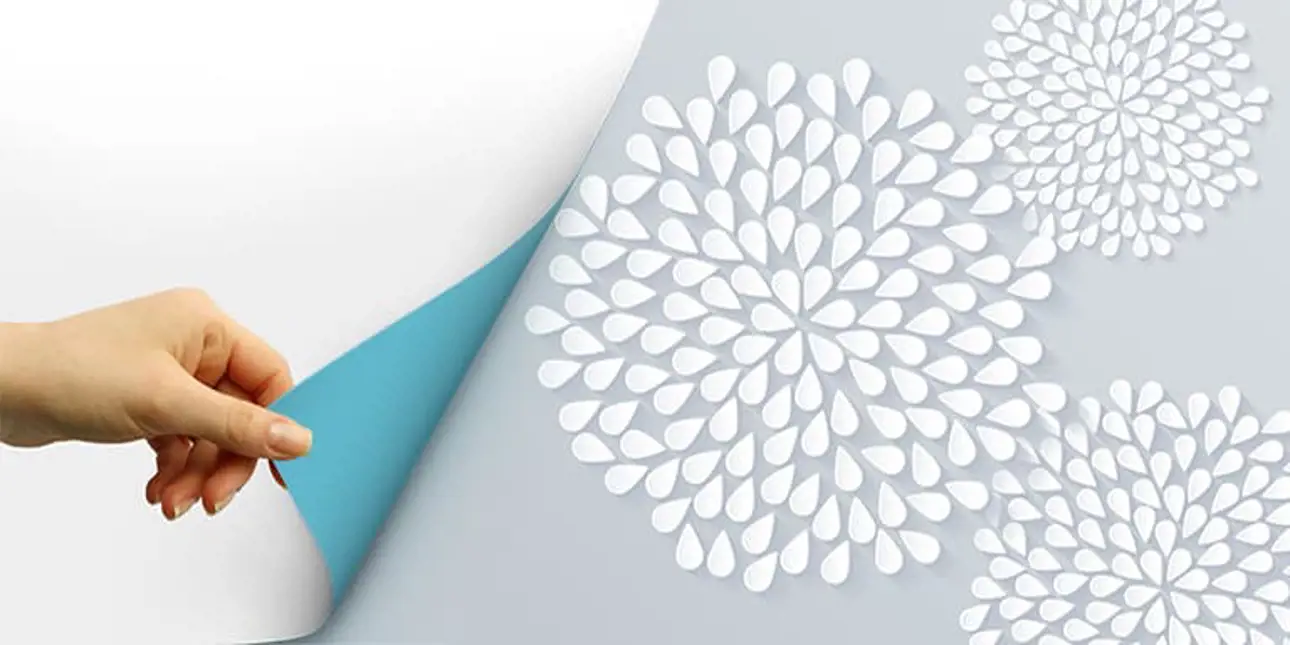

High surface quality all the way to finishing

Surface sizing, coating and calendering are the steps that can affect paper and board properties such as brightness, smoothness, uniformity, gloss, and opacity. Sizing and coating rebuilds are often used to enhance quality. The rebuild solution and scope depends on the desired goal. Calendering rebuilds are great opportunities for improving quality for all paper and board grades through better profiles and higher temperatures.

Good end product quality can still be spoiled by an uneven winding of customer rolls. Ragged cuts cause unnecessary customer complaints and uneven quality. Reliability, minimized surface core waste and excellent roll runnability in winding can be achieved with winder modernizations.

How to plan a successful rebuild?

Rebuilding a paper or board machine can improve the competitiveness of your business and your processes. But where do you start? Download our e-book to learn how to develop a winning rebuild concept, how to minimize rebuild related risks, and how to ensure smooth ramp up to full production.

Download e-bookExplore our latest board and paper press releases

- Jan 11, 2024Valmet to supply key technology for Shandong Jin Tian He Paper’s board machine in China

- Oct 25, 2023Valmet has received a major order of multiple technologies from Liansheng Pulp & Paper in China

- Oct 4, 2023Valmet introduces a new rotating consistency measurement for pulp and paper producers

- Sep 26, 2023Valmet to supply a fine paper making line to Yueyang Forest Paper in China

- Aug 31, 2023Valmet to supply key pulp and paper technologies to Naini Papers in India

- Jul 19, 2023Valmet to supply a high-capacity winder to Gascogne Papier in France

- Jul 4, 2023Valmet to supply an OptiFlo headbox and Valmet Conical Refiners to Shree Ajit Pulp and Paper Limited in India

- May 8, 2023Valmet to rebuild ITC’s board machine in India

- Apr 25, 2023Valmet to deliver key technologies for Henan Longyuan Paper’s testliner line in China

- Mar 27, 2023Valmet to supply a new container board making line to DS Smith in Italy