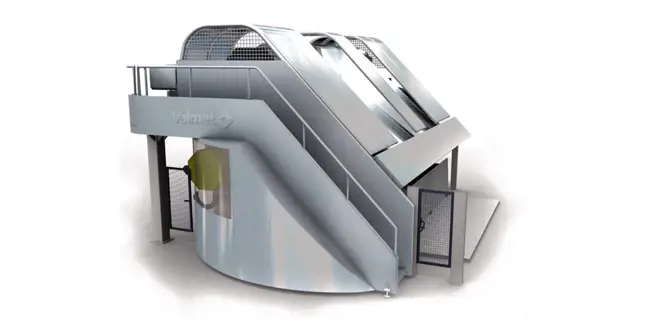

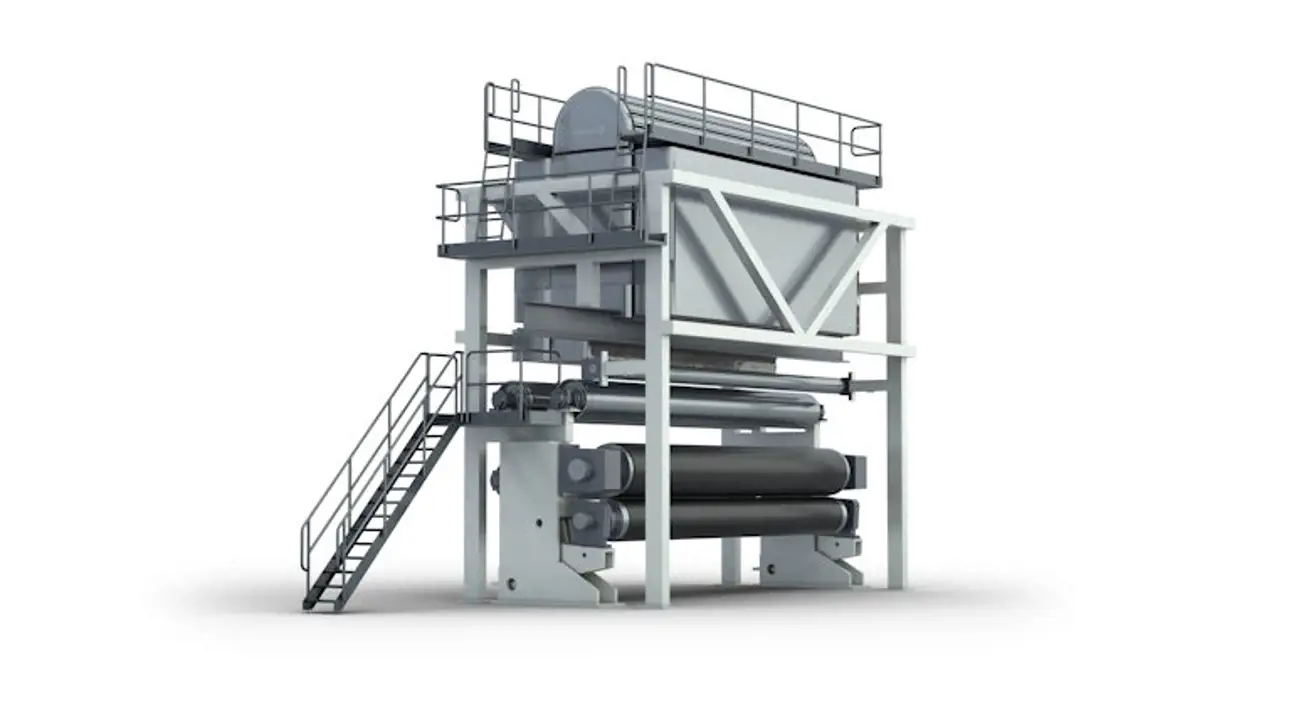

Double-pass cooling calendering

Valmet’s latest solution for bulk-saving is double-pass cooling calendering. This new patented technology improves the calendering results compared to usual production conditions. With conventional roll nip, the best calendering results are achieved when the web is cool and stiff, like in pilot trials. With double-pass cooling calendering technology, pilot-type conditions are brought to production-level, by cooling down the web before the calendering nip.

Raw material savings with higher bulk

Energy savings

Compact design - easy for rebuilds

More lightweight end-product

Double-pass cooling calendering enables the production of more lightweight end products without compromising functional and visual properties. This will lead to a substantial reduction in energy and raw material usage.

Web cooling is enabled by cool dry air blown on both web surfaces. Thanks to the compact design of this new technology, double-pass cooling can be retrofitted to practically any production line.

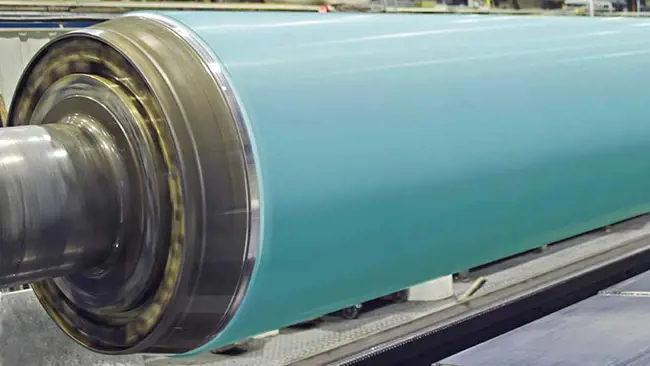

Cooler the web, higher the bulk

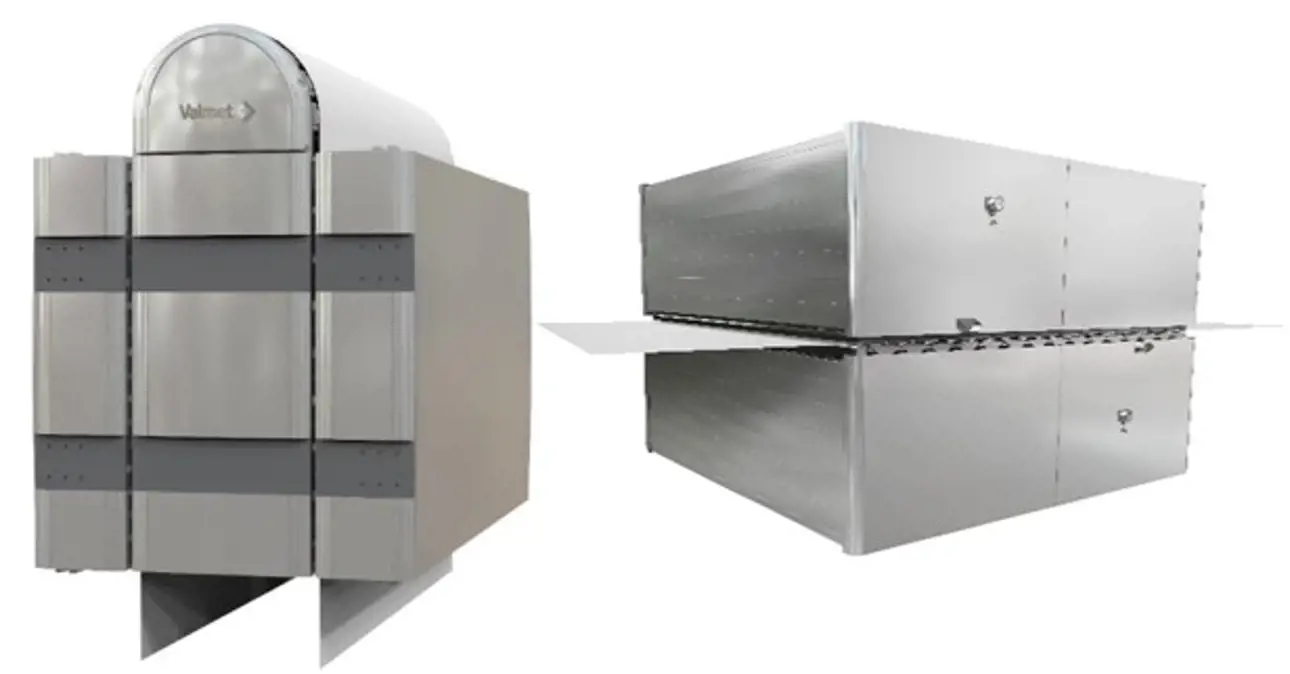

The dry air is blown on the web with the OptiDry Chill air web cooling units. OptiDry Chill double pass units presented on the left cool the web twice longer than the conventional cooling units on the right. For each 10 °C of lower web temperature, you'll get ~1 %-unit higher bulk!

Double-pass cooling technology complements Valmet's bulk-saving calendering offering, which includes the revolutionary metal belt calender as the ultimate lightweighting solution. With double-pass cooling technology, it is possible to get almost half of the metal belt calendering benefits with lower investment costs.

Want to talk to our calendering experts?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact our expertsRelated products

Interested in pilot trials?

Get in touch with our pilot trial experts to discuss how you could benefit from our pilot trial services.

Contact our pilot trial expertsLearn more about the services and automation solutions for calenders

How to plan a successful rebuild?

Rebuilding a paper or board machine can improve the competitiveness of your business and your processes. But where do you start? Download our e-book to learn how to develop a winning rebuild concept, how to minimize rebuild related risks, and how to ensure smooth ramp up to full production.

Download e-bookExplore our latest board and paper press releases

- Jan 11, 2024Valmet to supply key technology for Shandong Jin Tian He Paper’s board machine in China

- Oct 25, 2023Valmet has received a major order of multiple technologies from Liansheng Pulp & Paper in China

- Oct 4, 2023Valmet introduces a new rotating consistency measurement for pulp and paper producers

- Sep 26, 2023Valmet to supply a fine paper making line to Yueyang Forest Paper in China

- Aug 31, 2023Valmet to supply key pulp and paper technologies to Naini Papers in India

- Jul 19, 2023Valmet to supply a high-capacity winder to Gascogne Papier in France

- Jul 4, 2023Valmet to supply an OptiFlo headbox and Valmet Conical Refiners to Shree Ajit Pulp and Paper Limited in India

- May 8, 2023Valmet to rebuild ITC’s board machine in India

- Apr 25, 2023Valmet to deliver key technologies for Henan Longyuan Paper’s testliner line in China

- Mar 27, 2023Valmet to supply a new container board making line to DS Smith in Italy